In this article we cover:

- What is External Wall Insulation

- What buildings it is suitable to

- How much it costs and what grants are available

- How much insulation do you need

- Do you need planning permission

- How to find a supplier

- Tips on site during installation

- Watchpoints and illustrations

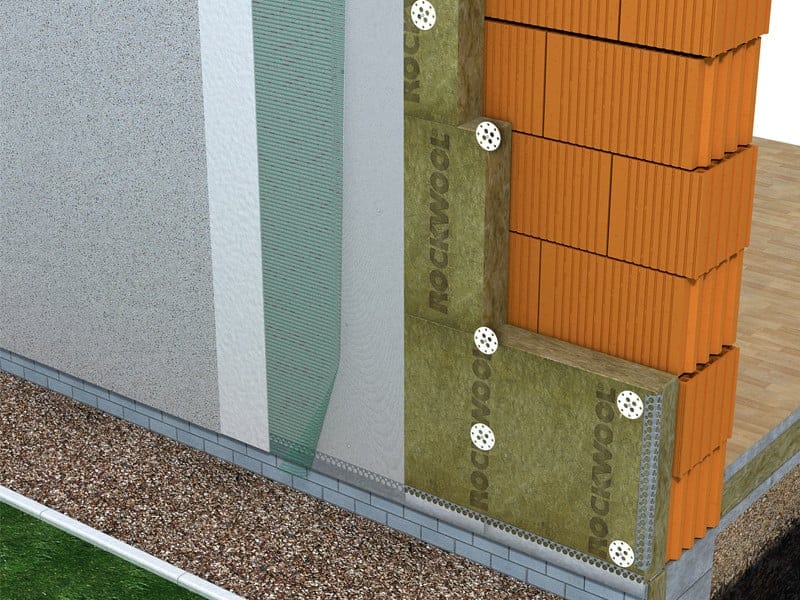

External Wall Insulation (EWI), which is also referred to as ETICS (External Thermal Insulation Composite Systems) is a method of insulating the outside walls of either a new or existing house, and involves directly applying insulation panels to the walls of the building before finishing with a rendering system to provide protection from impact and weather.

Whilst this method of insulating your home can be expensive when compared with other alternatives, it has numerous advantages which include not only increasing thermal performance, but also improving the overall airtightness of the home by eliminating air leakage through the external walls.

‘…it has numerous advantages which include not only increasing thermal performance, but also improving the overall airtightness…’

As compared to insulating from the inside this method has the benefit of not reducing your floor area; you are also less likely to run into possible condensation problems as you are in effect adding a layer of protection from the elements where they hit. However having a professional supply and fit the product is the key to a successful installation – there are many systems to choose from but all are proprietary and the people fitting them will have followed training courses.

Wall Insulation Cost

A ballpark figure for the supply and fit of an external wall is roughly £100 or €125/sqm excluding VAT. Every house is different and the circumstances in which the product is installed will have a bearing on cost; it’s advisable to get at least three quotations for your installation and compare like with like.

A common factor that will increase your quotation is the number of windows as these will all require a sill section and additional work to the head and reveal details. In an existing house if there are a lot of fixtures and fittings on the walls, the prep work will be more onerous.

Grants for homes built before 2006 are available in ROI.

In NI the Affordable Warmth Grant Scheme offers a maximum grant of £10,000 for houses with solid wall construction but your gross annual income needs to be less than £20,000.

Can it be used on any type of house?

External wall insulation is most suitable for masonry walls that are of either solid construction or cavity wall construction. Not generally recommended for timber or steel frame walls or when the wall is clad with timber.

So which insulation should I use?

There are a number of different manufacturers of insulated panels and these generally come in the form of either expanded polystyrene slabs or mineral wool. In ROI the National Standards Authority of Ireland (NSAI) provides guidance in relation to the application of EWI along with a comprehensive a list of Irish Agrément Certified EWI products so choose from this list. The NSAI has a directory of approved installers that can provide a guarantee and warranty for the installation.

In NI the British Board of Agrément provides guidance in a similar manner to the NSAI and provides a current list of Agrément Certified products, manufacturers and installers registered in NI (and the UK).

How much insulation do I need?

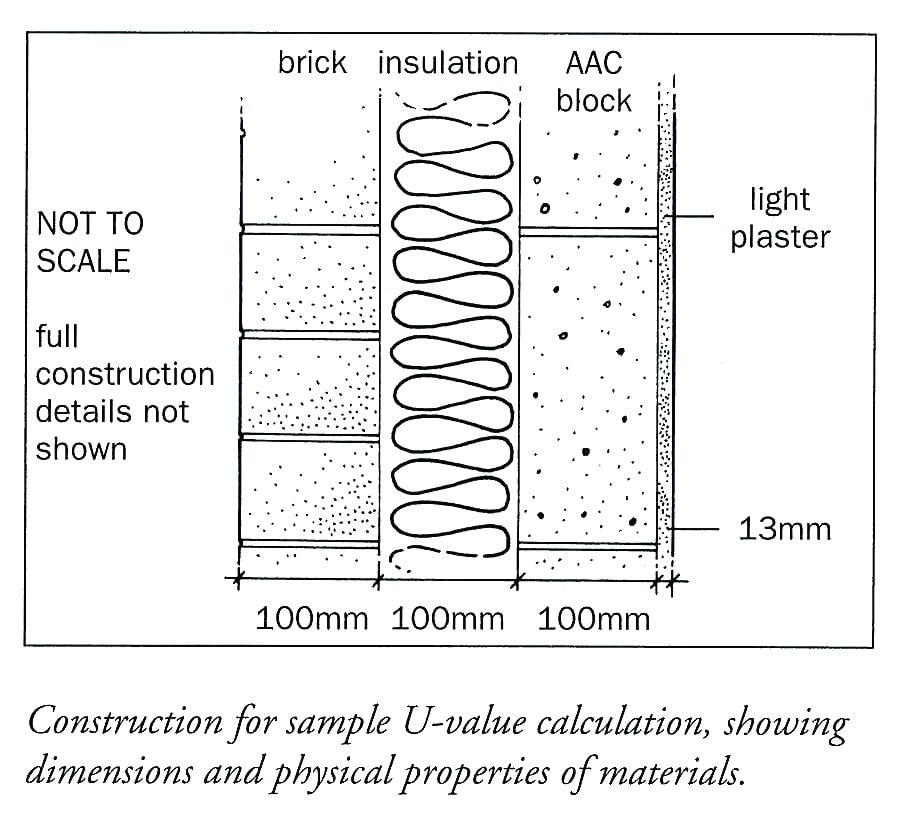

This will depend on the wall construction, the type of insulated panel and associated finishes you chose, but in ROI, generally speaking approximately 160mm of insulation would be required to meet the requirements of Technical Guidance Document Part L 2011 for a new build wall.

The heat loss requirements for an existing wall are not as high, and approximately 100mm of insulation is generally required to achieve the necessary standard. In NI the Building Regulations requirements result in approximately 100mm of wall insulation for a new build and approximately 50mm for an existing wall.

Do I need to secure planning permission?

In many cases external wall insulation will be exempt from planning permission. In ROI, the exemption clause in Section 4 (1)(h) of the Planning and Development Act 2000 states: ‘constituted works which do not materially affect the external appearance of the structure so as to render the appearance inconsistent with the character of the structure or neighbouring structures’.

Despite the fact that a layer of external wall insulation has been applied to your home, the selection and application of external render may ensure that the external appearance of the house is not materially affected. The requirements in NI are similar. If you have doubts, it is advisable in ROI to apply to your relevant local authority for a Section 5 Declaration to confirm whether the work is considered exempted development or if it will require planning permission.

There are indeed cases whereby external wall insulation is considered development and requires planning permission. Here’s an example of a recent case so do check with your local authority before proceding.

In NI either contact your local planning office or file for a Certificate of Lawfulness of Proposed Use or Development (Article 83B). In ROI if your home is listed as a Protected Structure or exists within an Architectural Conservation Area then a Section 57 application should be made to the local authority and the case will be reviewed in a not dissimilar manner to the Section 5 application.

This application is accompanied by detailed drawings of the relevant property and will therefore require the input of a professional (the requirement is often to have a minimum of a Grade 2 architect). In NI if the works are being carried out to a listed building or if the building is located within a conservation area then it is advisable to consult with the Department for Communities: Historic Environment Division.

In all cases due care should be taken to ensure that whenever the installation is complete, the thicker wall does not encroach or over-sail a neighbouring property as this may create legal issues.

On site

Similar details are applicable for both new and existing houses and, with careful planning and specification most issues can be resolved in advance of installation. Be mindful of the following: In the case of an existing house, all external wall surfaces must be clean and structurally stable.

The surface over which the insulation is to be applied must be smooth and suitable for the application of insulation material; any pebble dashed surfaces need to be removed in their entirety before works commence. If the wall is of cavity construction, it should be established if the cavity has been capped at wall-plate level. All gutters, downpipes, gully traps and other services associated with the external walls such as satellite dishes need to be carefully considered.

External Wall Installation Tips

Carefully consider how the insulation is formed around all windows and doors. Where possible the insulation should neatly meet the window frame so that there is a continuity of insulation.

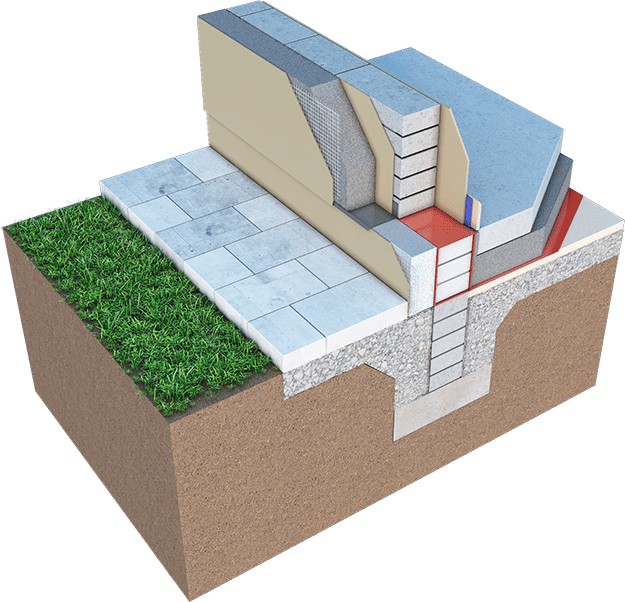

The insulation should start a minimum of 150mm over the finished ground level around the house, or along the line of the damp proof course of the house. A proprietary starter track is formed at this level by the installer to dress the underside of the insulation.If no damp proof course is evident then an injected DPC should be introduced to prevent potential issues with rising damp behind the wall insulation.

At eaves level the insulation should meet the layer of insulation associated with the roof, so that there is a continuity of insulation at this junction. It is important that the required path for ventilation of the roof area is maintained and not blocked as a result of this junction.

Expansion joints shall need to formed in the layer of external wall insulation to allow for expansion and contraction of the material over time. The exact placement and extent of these joints will depend on the product. With careful planning these can be arranged so that they form a considered part of the final appearance of the house.

Fire-stopping must be provided at the junction with a neighbouring dwelling so that there is no risk of external fire spread to an adjoining property. The material must be separated from a brick or block chimney by a minimum of 200mm from the flue pipe.

All fixings associated with the insulation layer should be formed in accordance with the product requirements to ensure the material is securely and safely adhered to the external wall surface.

Prior to the application of the finishing render and associated reinforcing mesh, all existing windows and doors should be carefully protected. In sunny weather rendering work should be carried out on the shady side of the house to prevent the render drying out too quickly or unevenly.

Proprietary corner beads should be formed to all exposed and vulnerable edges and fully lapped with the reinforcing mesh.

Upon completion, the contractor who has carried out the work should issue a guarantee that covers the entire installation and associated performance of the work.

[powerkit_collapsibles]

[powerkit_collapsible title=”Advice” opened=”true”]

External Wall Installation Tips

- Carefully consider how the insulation is formed around all windows and doors. Where possible the insulation should neatly meet the window frame so that there is a continuity of insulation.

- The insulation should start a minimum of 150mm over the finished ground level around the house, or along the line of the damp proof course of the house. A proprietary starter track is formed at this level by the installer to dress the underside of the insulation.

- If no damp proof course is evident then an injected DPC should be introduced to prevent potential issues with rising damp behind the wall insulation.

- At eaves level the insulation should meet the layer of insulation associated with the roof, so that there is a continuity of insulation at this junction. It is important that the required path for ventilation of the roof area is maintained and not blocked as a result of this junction.

- Expansion joints shall need to formed in the layer of external wall insulation to allow for expansion and contraction of the material over time. The exact placement and extent of these joints will depend on the product. With careful planning these can be arranged so that they form a considered part of the final appearance of the house.

- Fire-stopping must be provided at the junction with a neighbouring dwelling so that there is no risk of external fire spread to an adjoining property. The material must be separated from a brick or block chimney by a minimum of 200mm from the flue pipe.

- All fixings associated with the insulation layer should be formed in accordance with the product requirements to ensure the material is securely and safely adhered to the external wall surface.

- Prior to the application of the finishing render and associated reinforcing mesh, all existing windows and doors should be carefully protected. In sunny weather rendering work should be carried out on the shady side of the house to prevent the render drying out too quickly or unevenly.

- Proprietary corner beads should be formed to all exposed and vulnerable edges and fully lapped with the reinforcing mesh.

- Upon completion, the contractor who has carried out the work should issue a guarantee that covers the entire installation and associated performance of the work.

[/powerkit_collapsible]

[/powerkit_collapsibles]

In the case of existing houses these need to be removed in their entirety and re-fitted upon completion of the insulation layer. All surface mounted cabling must not under any circumstances be covered with insulation as this represents a fire risk.

The EWI installer is not permitted to move or relocate such cables and therefore must coordinate the work with the electricity supply company so that the cable can be unclipped from the wall, insulation installed and finished and then cable refitted within a suitable external duct. If the electrical meter cabinet is located within an area that is to be insulated then an extension shall need to be formed to the cabinet enclosure to allow the depth to be increased to match the finished face of the insulation.

Natural gas meter boxes, including the gas inlet pipes, isolation valves and meter box must not be covered or impeded by the installation of EWI. In advance of any work commencing it is advisable to contact the local representative of the gas company to determine what may be required in relation to the meter box and associated pipes.

If there is a flue pipe to either a gas or oil boiler then the terminal point of the flue must be extended and fire-stopping provided around the pipe.

UPDATE December 2017: New SEAI guide on external wall insulation is available here.