In this article, we cover:

- What is insulation

- How much insulation is the right amount

- What is airtightness and the importance of venitatlion

- What is condensation and thermal bridging and how to avoid them

- What the building regulations have to say about insulation and airtightness

- The difference between NZEB and passive house

- Why you need an energy assessment

- What is thermal imaging

- What is an energy rating

- Dealing with chimneys

What’s the difference between an NZEB and a passive house?

The terms passive house and Nearly Zero Energy Building (NZEB) both refer to designing buildings that require very little energy to run comfortably, i.e. low energy bills.

In the context of house building, a big difference is that NZEB is specifically referred to in Part L of the ROI building regulations, defined as a building with a very high energy performance that gets the very low amount of energy it still requires mostly from renewable sources, on site or nearby.

In practice, this means building a house that retains heat very well and installing some form of renewable system(s), usually in the form of a heat pump or solar panels.

Most designers will use the term passive to refer to the German PassivHaus Institute’s definition of a passive house, which is again all about hitting minimum energy targets based on the building fabric. The PassivHaus Planning Package (PHPP) was the first low energy homes design software that really took off in Ireland, and was in widespread use well before the ROI building regulations introduced the NZEB requirement.

The basic premise is that the home is designed to be so airtight and well insulated that your space heating demand will be very low, i.e. no more than 15kWh/sqm/yr for a new build or 25kWh/sqm/yr for a refurb. The German PassivHaus standard also includes mechnical ventilation with heat recovery as a requirement, but there is no mandatory renewable component although you can of course include renewables in the PHPP design software.

What is insulation and airtightness?

Airtightness is the ability of a system to prevent air leakage. Air leakage is driven by pressure differences across the building envelope.

Too much air leakage, and your heating bills will suffer due to the draughts. Important too is the fact that air leaks can lead to fabric decay due to dampness.

The less air leakage the better, but it is important that there is adequate and controlled air circulating in the building to provide good indoor air quality for the occupants.

The airtightness barrier can be integral to the material, e.g. spray foam insulation or even plaster, or can be added on with a membrane. Airtightness and vapour control membranes are placed on the warm side of the insulation to avoid condensation in the fabric (see Watchpoints below).

They are joined with proprietary tapes. Paint on airtightness barriers are also available.

Not all membranes are the same and need to be specified for the particular application.

The most common measure of airtightness is air permeability, referred to as q50, in m3/h.sqmK at a pressure of 50 Pascals. This is the measure used in the Building Regulations in ROI and in NI.

Air Changes per Hour (or ACH, also referred to as n50) are based on the volume of the building instead of the envelope area. ACH are often quoted to demonstrate the airtightness of a building, but this is not the measure used by the building regulations.

The Passive House standard specifies ACH in their methodology; remember that this is a voluntary standard and even if you design to this benchmark with their planning package (PHPP), you must separately prove compliance with the Building Regulation requirements with DEAP in ROI and SAP in NI.

In most cases you will need to pay for an air permeability test to prove compliance (see p108).

In the context of house building, insulation products are designed to reduce the rate of heat transfer across the building fabric.

Insulation limits the flow of heat energy between two environments that have different temperatures. So you will equally find insulation products around pipework and hot water cylinders to limit heat loss from your hot water, but also integrated within preinsulated products so as to prevent thermal bridging (see Watchpoints below), e.g. preinsulated steel or preinsulated window sills. Insulation can equally be integrated within the structure of the house.

How well an insulation product does its job is measured by its thermal conductivity. See p106.

The amount of heat you gain from the sun, through glazing, is known as solar gain. A well insulated house will retain this heat.

How much insulation is the right amount?

The main reason to insulate is to prevent heat from transferring from the inside to the outside, and vice versa, to save on your energy bills.

Unfortunately it is not a simple matter of increasing insulation thickness and getting the same increase in performance. This is only true up to a point and it is where you will start weighing in the cost of adding more insulation.

There is an optimum thickness for each type of construction based upon not just the performance of the material, but also the space available in the wall, roof or floor. Once this has been determined go for the best (i.e. lowest) possible U-value within reasonable cost.

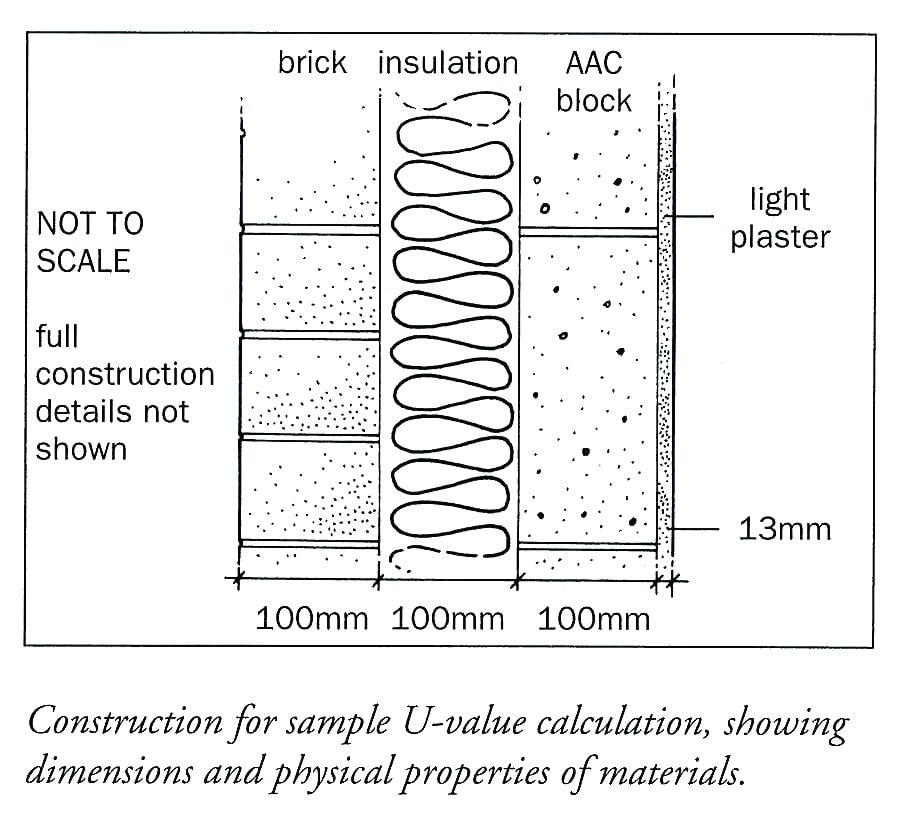

The U-value is the metric that shows you how well insulated your house is. It takes into account the entire build up of the wall, from the plaster/plasterboard to the external finish.

In technical terms it calculates the combined thermal conductivity of all the components, and thickness of each, to give you a measure of how well the building element reduces the exchange of heat between two environments at different temperatures.

The lower the overall U-value, the better the build-up is at keeping the heat in. Insulation is what most reduces this number.

Watchpoints

When putting together your construction drawings, which will specifically put on paper how to build your floor, walls and roof, your architectural designer should take into account two common pitfalls: interstitial condensation, and thermal bridging. Eliminating or minimising both is a requirement of the building regulations.

As you’ll have noticed on a single glazed window, where cold air hits a warm surface water droplets form. This is known as condensation. Interstitial condensation is when the same thing happens between a cold (say a cold external wall) and a warm part of your building fabric (say an insulated internal wall). The build up of water, which will be hidden behind the wall, roof or floor, can then lead to fabric decay and mould growth. Vapour control management is the way to prevent interstitial condensation, which is why your airtightness strategy is so important.

The Building Research Establishment (BRE) defines a thermal bridge, also called a cold bridge, as an area of a building construction which has a significantly higher heat transfer than the materials surrounding it. In places like Ireland, this can result in additional heat loss at these points.

This often happens where there is a break in the insulation (e.g. there are gaps in insulation due to poor installation), less insulation (e.g. it has been cut through to make room for pipework or other element), or the insulation is penetrated by an element with a higher thermal conductivity (e.g. in the case of a supporting steel beam).

A relative thermal bridge may also occur around openings due to a reduced thickness of insulation – to minimise this requires good details on the part of the architect, as well as good detailing on the part of the installer.

To estimate the heat loss at junctions in new dwellings, you will see reference to the Y-value, derived from the total thermal bridge losses. The lower the Y-value, the better.

Why you need an energy assessment

Integral to the design stage, whether new build or renovation, will be your energy strategy. This will dictate how much insulation you will be putting in and what level of airtightness you are aiming for.

The house’s shape and height will be two determining factors, as well as how much glass you plan to use. Insulated walls are much more efficient at retaining heat than windows can ever be, so a design with a lot of glazing will need to compensate with higher levels of insulation.

At the minimum, to do the energy calculations, you will need the input of a Building Energy Rating assessor (in ROI, list of accredited assessors

ndber.seai.ie) or an Energy Performance Certificate assessor (in NI, list of accredited assessors epcregister.com).

In a new build, they will check if the house design that you have complies, on paper, with the energy requirements of the building regulations. This is a crucial step. Building a house that doesn’t comply with the regulations will lead to costly remedial work down the line, so a provisional energy rating is necessary in ROI. Your provisional calculations must be uploaded when you file for your commencement notice, as they will prove compliance with Part L of the building regulations.

In NI, Building Control will ask for your design stage SAP assessment so even though the regulations are less stringent, you will still need to prove that your design complies and therefore get an energy assessment.

In a renovation project, an energy assessment will guide you on what upgrades are best suited to your property. Each building is unique, not only in its shape, size and year of construction but also because of the alterations that have been made over the years, potentially even including insulation upgrades. The energy strategy must be tailored to the specific building.

What are the regulations?

Minimum insulation and airtightness requirements are outlined in Part L (ROI) and Technical Booklet F1 (NI) of the building regulations for both new builds and renovations (only major renovations in the case of ROI).

Each element, be it a wall or window, must meet minimum standards (i.e. maximum permitted U-values); airtightness is measured as a whole but any leak in one area will lead to a considerably lower result overall.

In relation to ventilation (Part F in ROI, Technical Booklet K in NI) the key aim is to provide sufficient clean fresh air for the occupants. This means minimising the risk of condensation, mould growth or other indoor air quality problems by ensuring a minimum number of air changes. Filters can be added to mechanised systems to increase the air quality even further.

There’s also Part J in ROI, Technical Booklet L in NI, which are critical in relation to the supply of air for combustion appliances in a safe and efficient manner.

What is thermal imaging?

Thermal imaging are images that show different rates of heat loss from a building. This thermogram can thus highlight areas of air leakage. The cold air entering the house is shown on the image as shades of blue, indicating a draught.

A simpler way for detecting and visualising their presence is by using what’s known as a smoke pencil. Both professionals and DIY experts use these. They can quickly detect air gaps in discrete areas around buildings by following the smoke paths.

Build tight, ventilate right.

Current thinking has it that to save on your utility bills you should aim to achieve a high level of insulation and airtightness. But as ‘build tight, ventilate right’ implies, you will also need a well designed and well managed process for introducing fresh air and removing harmful household contaminants. Otherwise your home could become a health hazard. We do, after all, spend over 90 per cent of our time indoors.

It’s important to note that any type of building, airtight or not, must be well ventilated to keep the air quality level high. A well managed airflow, not draughts, is the best way of ensuring that we live and breathe fresh air within our homes.

Airtightness is particularly important where heat recovery ventilation is installed, as the system relies on being able to circulate air around the house and recover most of the heat content of the waste air to warm up incoming fresh air.

If the building is leaky, either or both of two things may happen – some of the warm air may be lost before its heat can be recovered – or cold air may come into the building without being warmed up first. Either outcome will reduce the effectiveness and efficiency of the system.

Remember too that building codes and regulations traditionally only control only air quantity, not air quality.

What is an energy rating?

Energy ratings exist throughout Europe and consist of a certificate that gives your house a grade, on an A to G scale, much like your washing machine or fridge (A being the best).

In ROI they’re called Building Energy Ratings (BER) and in NI, Energy Performance Certificates (EPC).

Similar methodologies (in NI Standard Assessment Procedure or SAP, in ROI Dwelling Energy Assessment Procedure or DEAP) are used to prove compliance with the energy efficiency requirements of the Building Regulations and to draw up energy ratings.

You must carry out an energy rating before you move into your newly built home. In ROI, in the case of a renovation project, you need a before and after energy rating to get your grant from the Sustainable Energy Authority of Ireland (SEAI).

Up/down the chimney!

Open fires were designed for a completely different era and mindset. While they gave out tremendous radiant heat, 90 per cent of this energy escaped up the chimney. And that’s only half the inefficiency story.

A roaring fire can extract an additional 90 per cent of a building’s other heat because of something we didn’t previously understand, even if its effect was known, namely the passive stack effect.