When building your forever house, you must factor in costs for each and every item, none more so than your external walls cost.

For cost purposes, external walls refer to the structure of the main external envelope of the property. In most cases it’s the main structural element and also the area that’s most visible and, along with the roof and windows, lends character to the build. The cost of external walls can inevitably be traced back to three main headings, those been height, makeup and finish.

The external wall will commence at the internal ground floor level of the property (the DPC level at which the substructure element stopped) and extend to the wall plate level of the roof construction.

Height of the walls

The height of the external wall structure will depend on a number of factors, including the number of floors. Intuitively you could think that the taller the building the more expensive it will be but that depends on the design and square footage.

A sprawled design may require more wall material than one that is stacked. There are two other important cost aspects in relation to wall height:

Floor to ceiling heights. The internal floor to ceiling height will immediately have a direct impact on the cost of the external envelope. In terms of the building regulations, Technical Guidance Document F (ROI) outlines a minimum requirement for a floor to ceiling height of 2.4m (8 foot) but this can seem quite low.

It is therefore not uncommon for properties to have 2.7m (9 foot), 3m (10 foot) or for striking effect, even up to 3.6m (12 foot). If you plan to use your roof space or convert it at a later date, in addition to making sure the joists are strong enough to carry the weight, there’s a calculation you have to make for the acceptable ceiling height too. The situation in NI is a bit less straightforward.

Depth of the floor construction. The depth of any intermediate floor slab will generally be in the region of 225mm to 300mm but it can be more or less depending on the design. A 2.4m floor to ceiling will therefore have a requirement of circa 2.7m of blockwork in each lift to cater for the floor structure between floors.

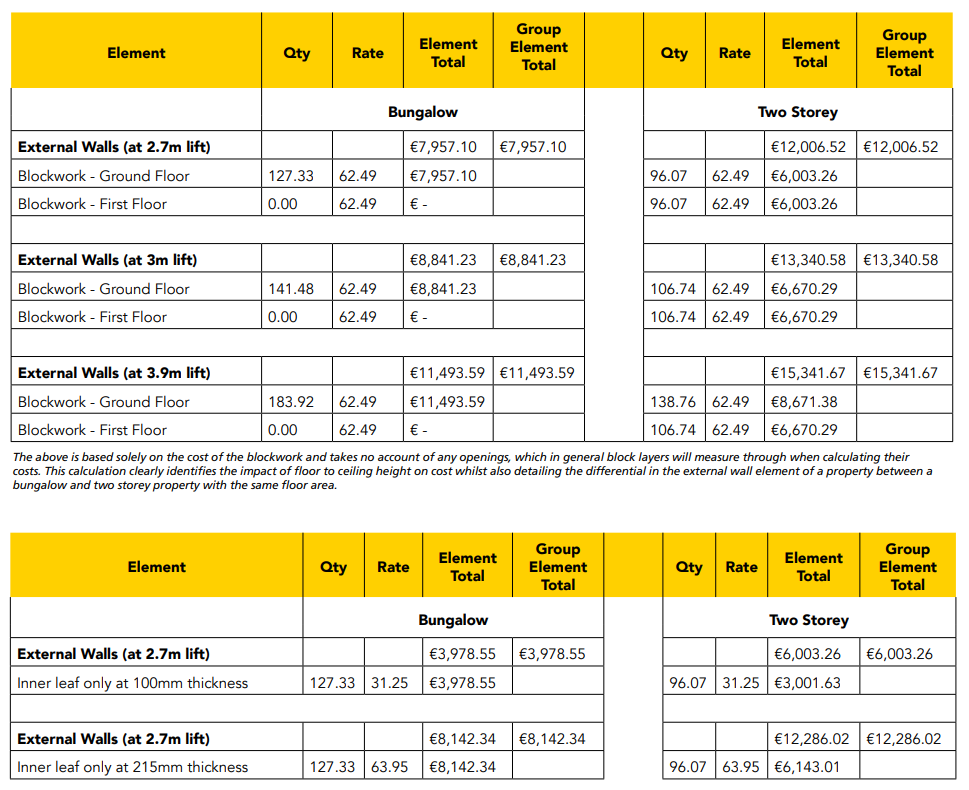

We outlined in the last issue that we would use a 139sqm bungalow and a 139sqm two storey property for the purpose of identifying the impact of design and material selection on costs. To identify the impact of floor to ceiling height on costs we analyse both property shapes for three different floor to ceiling heights.

The costs are based on a standard cavity wall construction with a 100mm outer leaf and a 100mm inner leaf of blockwork.

What the walls are made of

As one of the main structural fabrics of a building, the external wall element is a fundamental aspect to the calculation of the U-Value for any property. In ROI the new building regulations will require that the wall U-value be even more energy efficient than what was required in the 2011 edition.

Therefore the design, material selection and thickness as well as the overall makeup of the external wall element is now part of a complicated calculation system that can vary greatly from property to property in order to achieve the required overall U-value.

As I outlined in the previous issue, the cheapest way to build a house is usually the way our grandparents did. However with the new building regulations coming into force, traditional methods such as cavity blockwork are finding it harder to compete with newer methods of construction from a cost perspective.

That said the most common method of external wall construction is still based around the traditional cavity wall method. Timber frame has seen a revival in recent years, especially for large scale housing developments where speed of construction and off site quality control are important aspects.

External Walls Cost

I am covering the three most common wall build up types but there are others including ICF (insulating concrete formwork) which is increasing in popularity and modular construction (steel frame).

Cavity wall construction In order to comply with building regulations the current cavity wall makeup will generally include an outer leaf, a cavity with at least 125mm of insulation, an inner leaf and a drylining or insulated plasterboard finish.

The thickness of the internal insulated plasterboard will depend on the overall U-value requirement of the wall. The final cost of this item will depend on that selected thickness but on average the material cost of the plasterboard will increase by 10 to 12 per cent for every 10mm of insulation thickness.

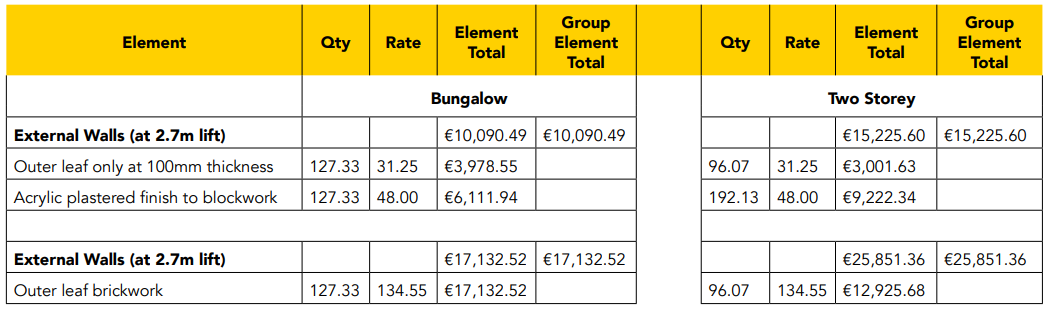

The inner leaf of blockwork will generally be either 100mm or 215mm in width. Where the inner leaf is not carrying the load of a precast floor slab construction it will generally be 100mm wide but 215mm will be required where precast or similar floor construction is required to be carried by the wall.

This change alone will double the quantity of blocks in the inner leaf of a cavity wall as outlined above. A 100mm wide blockwork wall has 9.88 blocks per sqm but a 215mm blockwork wall has 20.22 blocks per sqm.

The cavity is then generally either fully filled or partially filled with 100-150mm thick insulation (either board or pumpedin beads). Again the exact makeup and thickness of this cavity will dictate the final cost of the insulation materials. The brand and thickness of insulation will vary in cost but on average costs will increase with every 10mm of insulation thickness by about 10 per cent.

The blocks themselves can be standard concrete, insulative concrete up to insulative clay and costs will vary according to this.

Timber frame and Structural Insulated Panels (SIPS) construction The inner leaf will be the timber frame structure which will be specifically designed by a selected manufacturer. The cost will vary depending on the design, member sizes and required U-value and differs greatly from company to company.

Timber frame companies will cost their proprietary systems as a whole; the insulation is integrated in the wall construction makeup and this cost is included in the designed system. In standard timber frame you will get an option of different types of insulation, SIPS generally consists of OSB bonded with board insulation.

External wall insulation systems The inner leaf of blockwork is generally the only leaf and as such it is usually 215mm wide as it will form the loadbearing structure on which any floors and roof will rest. The wall is then externally insulated.

How the wall is finished

The outer leaf of a cavity wall is the main rainscreen element of the structure. It will generally not form part of any loadbearing aspect of the design and it can be finished in a number of ways. The outer leaf is most commonly a 100mm thick concrete block or a selected brick finish. Where a stone finish is required this will generally be installed to the front of a blockwork outer leaf.

The difference between the cost of an outer leaf of blockwork and brickwork will be substantial. Although a finished product (an outer skin of blockwork will require an additional finish, most commonly plaster) in itself, the cost of brickwork is expensive simply due to the quantity of bricks generally required.

Assuming the standard brick size you will get 60 bricks in every square meter. The cost of bricks can vary greatly depending on their makeup, colour and texture. In general bricks will range from €0.50 per brick upwards with reclaimed bricks costing multiples of that.

The below example compares the indicative cost of a 100mm outer leaf of blockwork with a coloured plastered finish (we will deal with plastering costs generally in a future issue of this series) and a brickwork external leaf on both of our sample properties. For the purpose of the example I have allowed for a brick at circa €0.65 per brick.

In a timber frame system the outer leaf will be installed in exactly the same manner as that of a cavity wall system but the blockwork will need to be tied in to the timber frame for structural stability.

Following completion of the timber frame kit erection, scaffold will be installed to the perimeter of the building and a selected outer skin of blockwork or brickwork will then be installed as outlined above. It is also possible to install a rainscreen on a timber frame kit using a cement board fixed directly to the timber frame finished in a plastered finish but at present this is not a vastly commonly used approach unless you want to finish the house with cladding.

In an external wall insulation system the outer leaf will in effect be the external insulation system. Costs on these systems vary greatly from manufacturer to manufacturer and it is advisable to shop around.

Some manufacturers will only distribute their product to a restricted and controlled list of installers, which helps with quality control. The external wall insulation system is most commonly finished in plaster or brick slip finish.

The cost of an external insulation system will generally be well in excess of that of other methods but it is seen by many as the optimal insulation and energy conservation system available on the market.

There are similar concerns in relation to cost for ICF wall finishes; discuss these with your supplier early on as a proprietary system may be required if you want a plastered finish.

Wall cost for window openings

External walls have openings for windows, doors and the like which will need to be factored into your costs. It is common for block layers to charge for their works “through openings”. In calculating the quantity of blocks to charge for on a project, block layers generally measure a building as if no openings exist.

This method has been used for generations with the cost of the work in the openings being used to pay for the cost of forming the openings. Whereas the labour may be dealt with in that manner, the materials required must be selected and calculated based on need. These include but are not limited to items like:

- Window sills (concrete, granite, reconstituted stone, insulated

- Lintels (concrete, metal (insulated or uninsulated) or steel as designed by the engineer on the project)

- Capping stones

- Quoin stones

- String courses (stone)

- Corbels (stone)

- Window head details (plaster or stone)

- Plinths (plaster or stone)

The selection of the materials for the above items will have a direct impact on costs for a project. Traditionally concrete was used for all of the above items but over time imported granite and stone alternatives have become commonplace but these generally come at a higher cost.

Due to concerns in relation to airtightness and thermal bridging, insulated products are becoming increasingly popular and have the advantage of being more lightweight and easier to deal with in terms of health and safety as well as quicker to install.

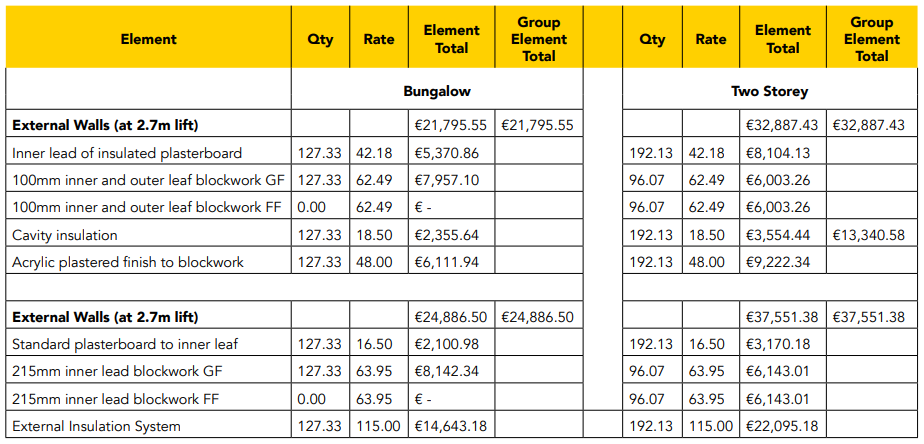

In order to pull this information together and to outline how again the various designs can impact on overall cost and budget issues on projects, the below example shows the comparison in external wall construction (excluding openings and accessories) costs of two properties of 139sqm floor area.

The two examples show the difference between a bungalow and two storey property with a standard cavity wall construction and plastered finish and the difference between the two properties using an external wall insulation system.

All rates have been left the same for the same works and it is assumed the

specification of insulations and the likes are the same on both properties. The difference between the cavity wall options is about €11,092 excluding VAT.

Whereas this is a small difference when compared back to average costing models of €79.79 per sqm (or €7.41 per sqft) it must always be remembered that it is merely for one element of a project and in most cases it is the sum of these types of differences that cause projects to run over budget.

The difference between the external wall insulation systems are even greater but the example goes to show the clear danger of budgeting based on average costs per square meter or square foot. The difference between a standard cavity wall bungalow of 139sqm and an externally insulated two storey property of 139sqm is approximately €15,756 excluding VAT which equates to €113.35 per sqm (€11 per sqm) and that’s before any accessories or scaffold are taken into account.