In this article we cover

- What is a structural floor

- What its uses are

- Most common choice of materials

Naturally when people look at a floor, they see only the surface, not the construction underneath. But designing a floor requires thinking not only about how it will look but how it can be used beyond something to merely walk on.

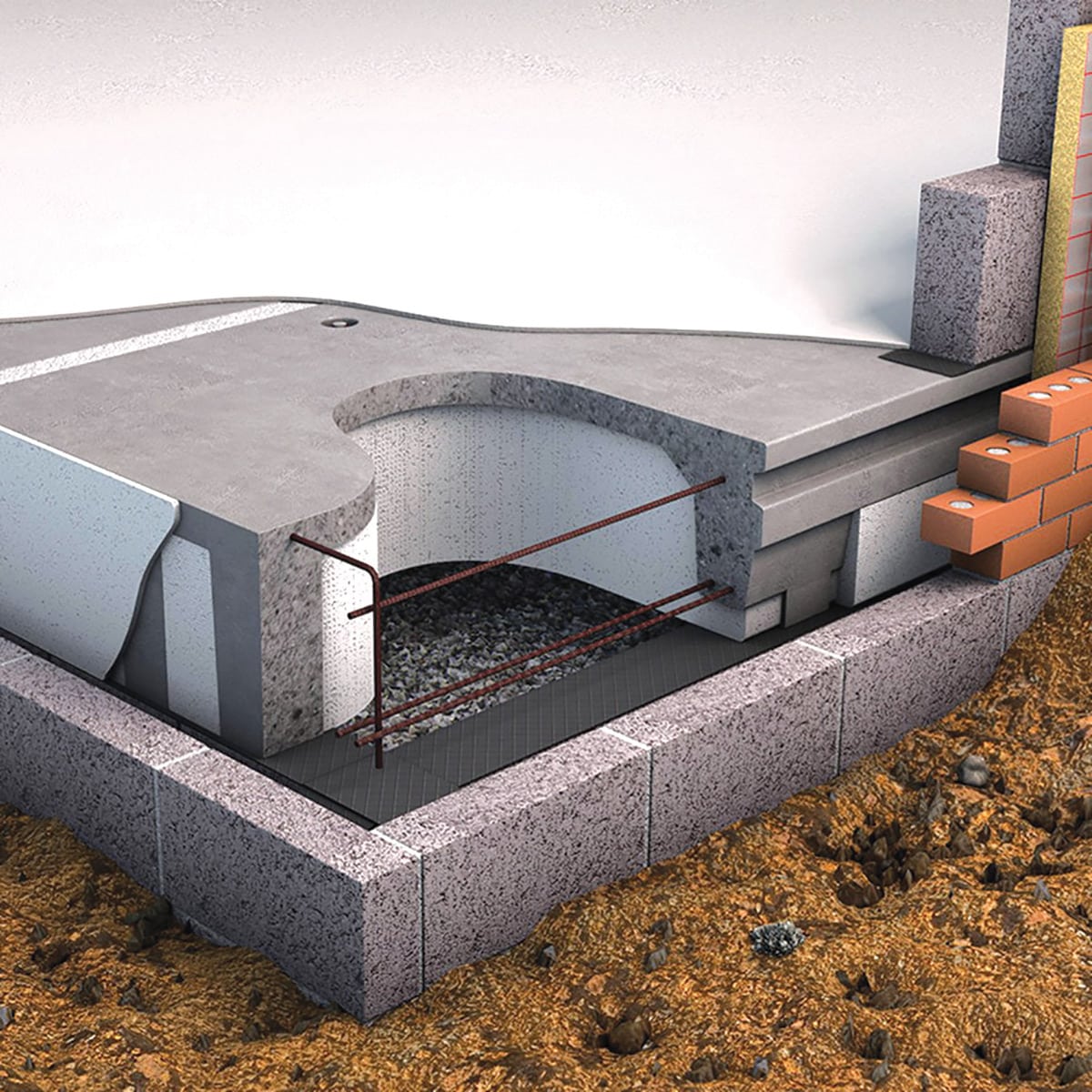

A floor is a level surface that can support the occupants and their furnishings and fixtures safely. It may need to also carry its own weight and internal walls and can also form part of the primary structure of a building, acting as a horizontal diaphragm to provide lateral support to walls.

Floors therefore need to be properly designed to account for their anticipated loading and use. In addition to general loads, larger point loads need to be considered. For example, a full bath and its occupant could weigh as much as a third of a tonne (double that for a cast iron bath), so they need additional support when placed on a suspended floor.

But a floor also serves to control extremes of noise, vibrational frequency and temperature. And in a ground floor, should prevent unwanted ingress of moisture, contaminants, gases and infestation from pests.

The choice of materials for the floor and its finishes will be based on aesthetics, economy, durability, environmental credentials and availability.

For instance, a floor made from solid concrete or similar dense materials can act as a heat mass by absorbing excess heat during the day and slowly releasing it at night. The solid floor, if given a suitably dark heat absorbent finish, can make use of solar gain in a highly glazed room, essentially collecting free heat to release as the room cools. In warmer climates, solid floors can become part of a passive cooling system.

Most floors can also be used to route services such as pipes, ducts and cables through them. The choice of floor construction can also be influenced by the intended floor finishes and whether underfloor heating is to be used, each of which may affect the build up of the floor and the thicknesses of the various layers.

Much of this guide deals with the design and use of structural concrete and timber elements, as these remain the most frequently used materials in domestic floor construction. Other systems that can be used for domestic construction projects, including steel or concrete frames, engineered timber, or composite steel and concrete deck flooring can be adopted from commercial or industrial floor construction techniques.

These systems offer additional scope for open plan house designs and the opportunity to use alternative systems and materials. Simple steel beams, of course, remain an economic and efficient way of supporting floors over open spaces and are easily repurposed or recycled at the end of the building’s lifecycle.

In terms of reducing embodied carbon overall, timber and any other plant based alternatives should be used wherever it is possible and feasible. A good design signed off on by a structural engineer will provide the correct solution for you.