Other ‘eco-considerations’

Brendan and Nicole’s heating and hot water demands are met by the district heating system, which feeds into a buffer “tank in tank” of 800 litres. The presence of this cylinder in the house increases energy efficiency by saving the district heating system from continuously circulating hot water in its pipe network. Another sustainable feature of the build is a grass roofed, unheated annex, on the east elevation, providing shelter to what is normally a cold side of any house. It stores the cylinder and pipes – as well as food! It is thermally separated from the main house and is therefore cold enough to be used as a larder.

The temperature of the district heating system is designed to motivate householders to install low temperature radiators, as this house did, or underfloor heating. The low calculated heat load for the house of 20 kWh/m2/yr makes this a suitable choice. It was felt that the radiators would be more responsive to meet the infrequent heating requirements of the house than underfloor heating and they were specifically sized for each room. They are also considerably less to install. Two heating zones provide individual temperature control for each floor of the house.

Hot water is also on a time and temperature control and the house has been designed to ensure the bathrooms and kitchens are close to the hot water tank to avoid long runs of pipe work. All showers are fed directly by the hot water supply, eliminating the need for electric showers.

Meanwhile, a heat recovery ventilation system provides a constant supply of fresh air. For this system to work effectively, the house has to be very airtight. Several evenings were spent sealing all gaps around openings and fitting a membrane at ceiling level to reduce air loss through the ceiling. The result was well worth the effort as an astonishing first airtightness test figure of 1.1 m3/ m2/hr was achieved.

Brendan and Nicole are delighted with the house they built – it’s warm, dry and healthy. Thanks to the hemp/lime, it will never be too humid indoors and it certainly will not be draughty, given their spectacular airtightness test result. The exterior and interior give no clue as to the uniqueness of its wall materials, and for me this is another advantage of building with hemp/lime – it doesn’t dictate the finished look of a house. The exterior render in fact consists of a basecoat and topcoat of different mixes of lime/cement render, designed to be moisture resistant and still breathable. A win win situation!

Site size: 750 m2

House size: 170 m2

Build costs: €200,000

Non direct costs: €25,000 (including Development Levy, Council fees and Site Management fee)

BER rating: A3

BUILD SPEC

Build type: Hemp-lime on timber frame, and aerated blocks

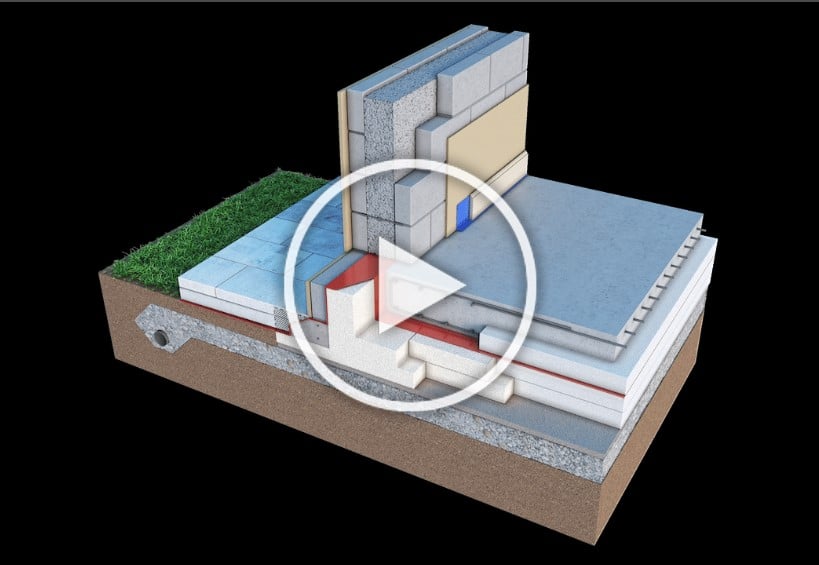

Insulation: The main attic has been insulated at ceiling level with 400mm blown-in cellulose (recycled newspaper). For the floors, 150mm of polyisocyanurate (PIR) insulation, was installed under a 150mm concrete floor slab. Aerated blocks were used around the perimeter of the slab which in conjunction with the edge insulation eliminated potential thermal bridges between the floor and external walls.

U-values: Attic roof achieved a U-value of 0.13 W/m2K. The flat roof has been insulated between the 225mm studs with cellulose to achieve a U-value of 0.2 W/m2K. The U-value of the 300mm lime-hemp wall is 0.22 W/m2K without any other insulating materials. The U-value of the floor worked out at 0.13 W/m2K.

Windows: All windows fitted are timber frame, triple glazed with argon filled low emissivity glass.

Niall Leahy BE MIEI supervised the construction of Brendan and Nicole’s home; he’s a Co Cork based consulting engineer with an interest in sustainable building projects. Churchtown, Midleton, Co Cork, mobile 087 9746382, www.leahyassoc.com