There is no doubt that a cantilevered staircase is one way of making a major visual impact.

To the casual observer a cantilevered staircase appears to be floating because it overhangs without any external bracings or supports. What holds it up is a counterweight hidden in the wall, out of sight.

Available in straight, quarter turn, half turn, helical and curved formats, it is usually the state of the walls and the position of the staircase that will dictate the type of underlying or hidden supporting structure used. A cantilevered helical stair can support the treads from a central column.

Generally speaking, it is more common for cantilevered staircases to be fitted in new builds and substantial renovations rather than in small refurbishment projects. Given the level of structural support required, installation in an existing building can be disruptive and will be more costly than in the case of

a new build wall that was purpose built.

In an existing house a structural engineer must be involved in the process given that the supporting wall is effectively an integral part of the staircase and that the calculations required in order to ensure the success of the work would have to be very carefully assessed.

Types

Each step of the staircase comprises a tread, two brackets, bolts and a telescoping support stud, which is installed in a concrete or steel beam, with the brackets protruding outward. A wall is then constructed around the brackets and the finished treads are then bolted into place. Depending

on the design and the wall, a reinforced metal sheet may also be required.

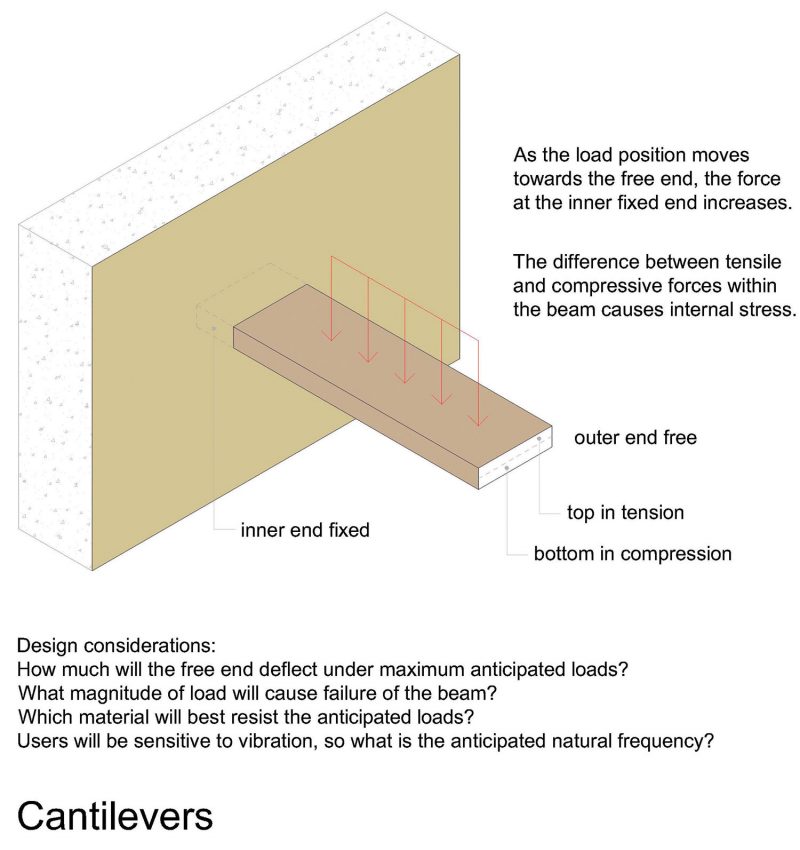

A cantilever is therefore a beam that is anchored at only one end, with the supporting structure carefully hidden within each tread and directly behind the face of the wall. How the staircase is installed will depend on logistics and on the supplier’s preferred modus operandi.

In cases where there is a steel- reinforced concrete wall, then it is common practice for prefabricated anchoring pockets to be installed within the framework of the wall before concrete is poured. Once the concrete has cured, the formwork is then removed and the treads are fixed in place.

If a cantilevered staircase is to be connected to a stud wall, steel strings with foot plates and anchoring pockets are fitted within the floor and wall to support the treads before the wall is plastered.

Alternatively, vertical steel supports for the inner stair string can span directly between the floors. In such cases, the weight of the treads may be shared by the support on one side of the frame within the wall and by a structural handrail or balustrade on the other.

Materials

The range of materials used in cantilevered staircases is wide and varied, although the most frequently used and the most popular tend to be stone, glass, timber, metal and composite materials such as engineered stone and concrete.

Glass stairs are particularly popular in houses where there is limited natural light, since the glass treads allow sunlight to filter down the different levels, thereby illuminating interiors. The glass treads are made of toughened and laminated glass and are often 32mm thick but calculations will have to be made to determine this.

The choice of material not only determines the method in which the staircase is supported – concrete and heavier timber will require more support than, say, glass – but will also impact the price of the job.

Handrails

Chances are you will need handrails so consider how that will impact on the floating aesthetic. That said in NI there is no need for handrails beside the bottom two steps.

In both NI and ROI handrails are necessary on at least one side if the staircase is less than one metre wide and on both sides if it’s any wider. Additional to this rule, (in NI) where a private staircase is part of the circulation route within the entrance storey of a dwelling or gives access to the circulation route within the principal storey of a dwelling, it should have a continuous handrail on each side.

There are handrail height restrictions too, 900mm to 1000mm in NI for both stairs and landings. In ROI the top surface of the handrail should be between 900 mm and 1000 mm measured vertically above the pitch line, and between 900 mm and 1100 mm above the landing.

Cost

The cost depends on the design, materials and size. Each of these elements can significantly hike the price but a ballpark figure for complete bespoke design, manufacture and installation would appear to be around the 15,000 mark (pounds or euros).

Regulations

Cantilevered staircases must meet the staircase requirements set out in the building regulations (TGD K in ROI and Technical Booklet H in NI), e.g. the treads must be a certain distance apart, headroom accounted for, etc. Consult with your building control officer in NI and your qualified architectural designer in ROI.