Steel frame construction is increasing in popularity in Ireland; we look at what this modern material has to offer and what you need to know about it.

In this article we cover:

- How steel frame houses are built

- Comparison with other building methods

- Pros and cons of steel frame construction

- Manufacturing process

- Frequently asked questions about steel frame construction

- Other uses for steel with pros and cons:

- Metal roofs

- Rainscreen cladding

- Stainless steel

Steel is widely used throughout the construction industry, as a structural support, yet many of us overlook the potential of steel frame as a building method when self-building.

You will actually be using it in one way or another as it performs ‘heavy-duty’ functions with ease – from reinforcing bars (rebar) in foundations, and precast to Insulated Concrete Formwork (ICF), and the structural elements that actually hold the building up.

Because it’s so versatile, it’s also great for all kinds of detailing, from stairs and balustrades, to decorative features and stainless steel kitchen. Here’s what you need to know about this versatile material.

Steel-framed homes

Timber-framed houses are very familiar to us, but steel framing for domestic builds is less well known in Ireland. The big advantage of steel is its design flexibility.

If your house is a simple design, then steel probably doesn’t add up cost-wise, but anything more adventurous than this and you’re on to a winner. It’s possible to make just about any shape or space in light steel.

The starting point is a rolled steel frame – the light steel then infills this to form the inner leaf of what would otherwise be block work. The outside skin can be anything you like, including steel, but most people choose a masonry or a rendered finish.

With effective insulation between the two skins and in-built drainage and ventilation, the external wall is complete.

Showing the steel skeleton as a detail can be very effective. It is, for example, exceptionally easy (and thus cheap) to create balconies and other structures that fall outside the building’s envelope.

One of the other attractions of steel framing is that wide spans are possible – far longer than anything in timber, except perhaps Glulam, which is very difficult to recycle. Indeed while steel will virtually span to any length with the help of deeper sections, Glulam is more limited.

However considering the spans required in a house Glulam is usually a viable alternative. Wide spans enable you to be really creative in design terms, with the internal layout. Steel also provides very accurate dimensions, hard to achieve with masonry skins.

The ‘stick build’ method is what most people use (rather like a timber frame only with light steel); there are also panelised systems, some of which can be pre-insulated and even have ties welded to the exterior surface to take brick or stonework.

This type of system can be load-bearing, with the result that no rolled steel elements are required at all and its strength means that concrete upper floors are simple, cost-effective to create and able to accept loads within a day or so of placing the concrete.

Steel frames are an excellent solution when working on uncertain ground, or when adding extra storeys to an existing building. After ‘decapitating’ the original structure and installing a concrete ring beam, a whole new storey or two can be added if the foundations will take it. This is because steel framing used in this way is 30 per cent lighter than masonry.

Good steel frame companies will take your design, do all the engineering calculations for you and deliver a steel package that they, or others, can install. This is an attractive feature to architects or other designers who may have limited experience of steel-frame building.

All the window and door openings are ready-made, and just about any level of pre-finishing complexity can be achieved to reduce work on site. There is a cost for this, but it could be the difference between building during the winter or not.

Questions people often ask:

- Will my steel-frame house rust? There’s no risk of rusting provided the frame is galvanised and the cavity between frame and outer skin drained and ventilated to reduce any risk of corrosion.

- What if it catches fire? Just like any construction, steel framed homes must meet Part E in NI, Part B in ROI. With light steel builds this is done by using fire-rated plasterboard linings. The number and thickness of the boards will depend on the fire rating required. Intumescent paint can also be used.

- Can I get a warranty for my steel-framed home? Yes.

- Will I be able to get a mortgage and insurance? Yes, insurers and mortgage providers are happy to underwrite steel framed homes as they are believed to have a lifespan well in excess of 60 years. In fact because of their ease of repair, durability etc., costs can sometimes be lower than for masonry or timber frame builds. Warm frame construction, where the lightweight steel is enveloped in insulation in a way that ensures the dew point is outside the frame and thus minimises condensation on the frame, makes sure that nothing can rust.

- How about extending later? This is particularly easy. Although you should always obtain professional advice first, in general, downstairs windows can be made into floor-to-ceiling openings and because of the large spans, internal refurbs are easy to achieve. It’s also simple to add extensions.

- What about cost? The cost of the steel framework is only about 12-15 per cent of the total build cost so factors such as labour and the other materials used are obviously much more significant when calculating the overall price. Because steel is strong, predictably dimensioned, enables a ‘precision’ build, is stable and there’s no drying out, cracking, or other such snagging to worry about, the building envelope is completed quickly and first fix trades can start almost immediately, saving time and cash. Similarly, follow-on trades are not held up.

- What are running costs like? Like timber frame, because of the way they are insulated, light steel buildings have low thermal mass so heat up and cool down quickly. Air-tightness is a real concern today, and steel doesn’t disappoint. Given careful attention to construction detailing, steel-framed buildings can outmatch the air-tightness of traditionally-built structures.

- Does all the framing and structure have to be in steel? Not necessarily. For example, timber roof trusses are still the most cost-effective way of creating a normal roof, even if you use steel for practically everything else. Of course, the minute you go for an unusual roof shape or internal exposed structure to make more living space, steel comes back into its own.

- Are there any health benefits? There might be. Steel framing doesn’t need treating with chemicals in the production process or later, (unlike timber), because it can’t become infested by worm or fungus, so you’ll never be exposed to the toxic chemicals that are sometimes emitted from treated timber.

Manufacture

Iron ore is the most plentiful substance in the earth’s crust. Steel is an alloy of this ore and various other elements such as carbon, manganese, chromium, vanadium and tungsten. The proportions and nature of these elements create steels of differing properties – and thus different end uses. For example, higher levels of chromium produce a rust-resistant, ‘stainless’ steel. Specialist steel like this is, of course, much more expensive than ordinary construction steel.

Steel has substantial embodied energy due to mining, transportation and manufacture, but it isn’t nearly as environmentally unfriendly as you might think. Steel production does emit quite high levels of CO2 compared with other materials on a tonne-for-tonne basis, but it goes a lot further.

There are two manufacturing routes; one is from iron ore, which requires coke and blast ovens, the other is from scrap steel. Worldwide steel production from iron ore is dominant (70 per cent) but in developed economies there’s more production emanating from recycled steel as demand is closer to the availability of scrap metal.

Energy consumption and carbon dioxide emissions from European steelmaking have been reduced by 50 per cent and 60 per cent respectively over the past 40 years and work is underway to lower this further. Due to the need for a blast furnace, as with the production of cement, one of the most promising avenues is Carbon Capture and Storage whereby CO2 is safely trapped underground. A European-wide research project called ULCOS is investigating the most appropriate routes for further reductions in energy use and CO2 emissions, see www.ulcos.org.

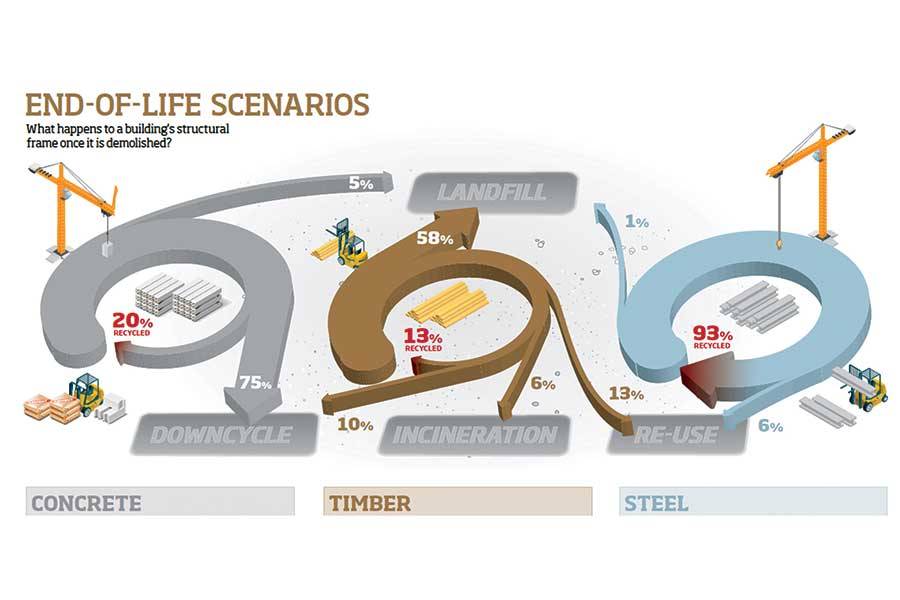

While steel can be reused, due to new builds requiring products to be certified, recycling is more common. In fact for over 150 years it’s been far cheaper to recycle steel rather than start from scratch; in 2014 scrap structural steel fetched £100/€125 per tonne. Since it can be recycled again and again without losing any of its properties, and the energy saved by manufacturing new steel from scrap is about 70 per cent, its embodied energy reduces with every new incarnation. A recent survey found that, of the waste steel construction products in the UK, a 91 per cent recycling rate was achieved while 5 per cent of the steel was reused and 4 per cent was lost, presumably sent to landfill.

Steel by-products are also valuable, e.g. blast furnace slag is commonly used as a cement replacement. Sustainability isn’t just about production; steel is intrinsically a low-waste product. On site there’s little or no waste because what gets delivered is used in its entirety, whether it’s structural or prefabricated. Finally, the large open span that a steel building creates makes it easy to refurbish and re-configure the internal layout without demolishing the whole structure.

Foundations

Although most people think of foundations as being simple masses of concrete poured into a hole in the ground, there are often many other elements involved. First, concrete is a material that is very strong in compression but relatively weak in tension. To compensate for this difference, steel bars known as reinforcing bars (rebars) are built into the concrete to enable it to carry high tensile loads.

Of course, it would be technically possible to reinforce concrete with just about any material with enough tensile strength but where steel is so good is that it has much the same coefficient of thermal expansion as concrete. This means that there isn’t too great a difference between the expansion of the two materials, which could otherwise tear the concrete apart.

The steel rebar that is used to reinforce concrete has ribs that help bind it mechanically to the concrete but it can be pulled out under extreme forces. This can be overcome by many specialised methods but they are rarely used on an ordinary domestic building site.

Normal rebar is made of unfinished, tempered steel, which means it can easily rust. Having sufficient concrete cover can help prevent this, but too much can result in cracking, and water ingress. Once water gets inside concrete in this way it makes the steel rust.

Because rust has a larger volume than steel it starts to build up pressure, leading to cracking, spalling and even, eventually, actual concrete failure. This is known as ‘concrete cancer’. In sophisticated foundations, or where concrete is used to cover above-ground structural steelwork in vulnerable environments, rebar can be coated with epoxy, galvanised, or even be made of stainless steel.

It’s vital to remember that in all but the simplest of deep trench-fill foundations (where the concrete itself does most of the work) all other types of reinforced concrete rely for their strength on the steel content rather than that of the concrete.

When forming edge beams, rafts, and other types of specialist foundations (including floor slabs) the strength comes from the steel being correctly specified. A suitable steel mesh for the average floor slab is A142 but it’s important to talk to a professional to be sure you get this right for your particular job.

All rebar steelwork should be connected by wiring the various rods, meshes and sections together. This is not only cheaper but also structurally more effective than welding. Welding induces weakness in rebar and is thus best avoided.

Steel for use in pre-stressed concrete must never be welded. When installing a steel mesh, be sure it’s near the bottom of the concrete. Fifty to 75mm of concrete underneath is usually enough. Prop up the mesh on proprietary spacers or use pieces of brick, concrete block, or other suitable material. When placing your concrete, ensure that this gap is maintained and that the mesh doesn’t end up on the bottom of your trench. It won’t do any good there.

Lastly, a word about safety. Always cover the protruding ends of rebar so workers and others don’t impale themselves on them. You can bend the ends over or, better still, use plastic ‘plate’ caps or ‘mushroom’ caps. It’s easy to sustain very nasty cuts and injuries from unprotected ends of rebar.

Before we leave foundations I should just mention sheet piling. If there is the potential for water penetration, soft soils, or need to shore up a dangerous bank while constructing a more permanent concrete retaining wall, for example, you might have to use steel sheet piling. In some situations steel piling can be driven into the ground (usually with a percussion hammer or an hydraulic ram), and left there forever.

This method is commonly used for river banks, jetties and so on. It’s a job for your engineer as it’s specialised work and can be expensive. He’ll guide you on the most cost-effective solution and will know the best installation system that will cause the least damage (from vibration), and noise annoyance to your neighbours.

Structural steel

Steel is an extremely strong material and very stiff in relation to its cross-sectional area. The common sections of structural steel include:

I-beams, universal beams, channels, hollow sections (square, rectangular and circular); angles;

T-shapes, and more. ‘Bars’ are flat pieces of steel that are not very wide; ‘rods’ are solid sections that are round or square; ‘plate’ is a sheet of steel that’s usually thicker than 6mm; and then there are various types of steel open-web joists.

Whenever structural steel is required, it must be professionally specified and designed very carefully. This is not a DIY job, even for an experienced self-builder. Steel is expensive so it makes sense to employ professional help to calculate the cheapest way of achieving the result you want. Sometimes this price has more to do with the way the structure is constructed off-site and erected on-site than with the actual cost of fabricating the steel. Tempting though it might be to bring all your steels to site in huge sections of pre-assembled units, it’s not such a good idea if the route to it can’t cope with the width and weight on the lorries.

The beauty of structural steel is that it comes to site ready-made; there’s very little, or even no, wastage; it goes up fast and forms an extremely strong ‘frame’ on which to fix other building materials. The downside is that it does not perform well in a fire and has to be protected. Although steel is non-combustible, it begins to lose its integrity when heated above 400degC and at 500degC loses about 50 per cent of its strength. Part B (ROI) and Part E (NI) of the Building Regulations set out the minimum requirements relating to the fire-proofing of structural steel. In domestic builds fireproofing is most easily and cheaply achieved by using a light-weight, galvanised steel framework around the steel which is then covered in fire-grade plasterboard. The half-hour resistance required can be achieved by 12.5mm board but if you want you can double this for peace of mind. Concrete of professionally-specified thickness is also a good fire-protector for structural steel members.

If you’re using steel in a roof structure, and the steel supports only the roof, it’s not necessary to protect it from fire, but if there’s steel in a dormer or any part of the floor support, these members must be fire-protected.

One of the most popular uses for steel is for a lintel. These are beams that bridge the head of an opening such as a window or door, (both interior and exterior). Concrete lintels are cheaper and very popular but steel lintels can be insulated and are particularly good for unusually shaped openings. Indeed proprietary steel lintels often combine integral insulation that prevents cold bridging. Steel lintels are also essential if you are using brick or stone as a facing.

Steel, in the form of stainless steel, is needed for wall ties which you’ll be using a lot of if your construction is of masonry (brick, block or stone). They need to be inserted at a rate of about 3.5 ties per square metre of masonry. There are special ties made for joining a timber-frame inner leaf to a masonry outer one. On average, you’ll probably use about 500 wall ties for a medium-sized detached house.

Walls ties hold the inner and outer leaves of a building together, maintain a fixed space in between for air circulation; prevent penetrating water from bridging the gap; and allow insulation boards to stay in place. An ongoing battle is ensuring that mortar isn’t dropped onto the ties during building. If it is, a bridge is formed across the tie, the gap is now compromised and water can move across by capillary action from outer to inner skins. Ties should always be checked at the end of every working day and, if necessary, any excess mortar washed off with a hose or watering can.

Finally, while precast concrete floors are widely used nowadays thanks to their fire resisting and sound reducing characteristics, there exists the option of steel decking. This spans between extra-wide inner leaves of block work, and/or specially designed steels, to create a membrane that is then flooded with concrete. The decking is supported until the concrete cures, thereafter the floor can take huge loads. This allows upstairs rooms to be built entirely where you want them (they don’t need a wall underneath to take the loads), and can easily be screeded to take under-floor heating pipes. The fire-proofing and noise reduction properties of such structural floors also make them popular. This is a useful alternative to situations where ready-made concrete floor beams cannot be brought to site.

Metal roofs

Metal is a good material for covering roofs because it is lightweight and strong (it has a high strength-to-weight ratio); is non combustible (although it does start to lose its properties in temperatures of 400degC or above), spark resistant, very easily recycled, and long-lasting. Metal also allows considerable design flexibility and most metal roofing requires minimal, or even no, maintenance; you can choose from copper, zinc, stainless steel, aluminium and plastic coated steel. Worldwide, corrugated steel (‘iron’) sheeting is one of the most commonly-used roofing materials.

If you wish to explore having a steel roof, go to a specialist company with your architect’s drawings from which they can create a CAD (computer aided design) picture of how it might look; you’ll be surprised how creative they will be. They’ll also deal with all the technical issues such as thermal expansion, rainwater and snow loading, guttering and rainwater disposal and, of course, insulation which is particularly vital because steel is a very good heat conductor.

Rainscreen cladding

This type of exterior finish is really just an extension of metal roofing. There are many companies offering a large range of products for both applications.

A rainscreen is constructed from a sub-frame that then carries various types of facing materials. These can be tiles, boarding, stonework, aluminium, timber and, of course, steel panels. Although rainscreens are mainly found on commercial projects, there’s no reason why you can’t have one on your home, especially if it’s of a contemporary design.

The rainscreen is a stand alone structure, it has no structural function. The outer layer keeps the weather out while the inner one provides insulation, prevents excessive air leakage, and carries wind loads. The outer layer allows the passage of air and helps to reduce energy loss. The cavity between the two skins is kept open and ventilated just in case any water penetrates the outer, protective skin.

Rainscreening has several advantages: it prevents thermal bridging, minimises temperature fluctuations because the insulation is on the internal skin, and maintains a ventilated cavity which prevents condensation on the outside of the structure. On hot days, heat is vented up the open cavity by natural convection, thus reducing heat gain to the building.

Stainless steel

This type of steel has a very high chromium content. Normal (carbon) steel rusts when exposed to air and water and eventually, apart from looking unsightly, it loses its structural strength. The chromium in stainless steel forms a protective coating that gives it its unique properties. Also, when stainless steel is scratched it repairs itself by a process known as passivation. Aluminium and titanium also have this property.

There are more than 150 grades of stainless steel of which only about 15 are commonly used. Because it is so inert, it is excellent for storage tanks, kitchen work surfaces and appliances, wall ties, balustrades, handrails, flues and chimneys, sinks and splash backs, and rainscreening, to mention some. In very exposed (especially marine) locations, stainless steel ironmongery, screws, nuts and bolts can be essential because they are able to withstand the effects of salt water.

The downside to using stainless steel in the interior is that it shows finger-marks easily and can create glare where either sun or artificial light falls directly on to it. It’s not difficult to clean, but may be an aspect worth bearing in mind if you have a young family as it stains easily (finger and water marks) and requires frequent buffing to keep shiny.

Andrew Stanway.

Additional information: Andrew Way of the Steel Construction Institute www.steel-sci.com and chartered engineer Jim Kelly of James Kelly Associates, www.jimkelly.ie. Statistics in Manufacture section from www.steelconstruction.info. Also see the Light Steel Forum website www.lightsteelforum.co.uk