If you’re thinking of installing an air to water heat pump, find out what your options are what to look out for.

In this article we cover:

- How heat pumps have become mainstream

- Types of air source heat pumps from split to monoblock

- How much they cost in both NI and ROI

- System sizing

- Which homes heat pumps are suitable for

- How heat pumps work

- Installation and maintenance watchpoints

- Alternatives to air source heat pumps

A round the turn of the millennium, the market for heat pumps in Ireland (north and south) was still in its infancy – only a handful of heat pumps were being installed each year. In 2013 there were around 7,000 units in ROI (all building types) and by 2020 the figure had risen to around 56,000.

Indeed, heat pumps are now the heating system of choice for new builds. And that’s likely to continue to be the case until hydrogen fuel cells become practicable. Heat pumps are cheaper to run than fossil fuel boilers (when correctly installed), only need electricity to work and will make your life easier to comply with the building regulations.

Whereas most of the early heat pumps were ground source or water source, air source heat pumps now dominate the market in both NI and ROI.

This is due to two main factors: air source types are much simpler (and thus cheaper) to install as they need no ground/water loop or borehole. And the efficiency of the heat exchangers has improved dramatically in recent years. But there are alternatives to consider (see page 91).

Types of air source heat pumps

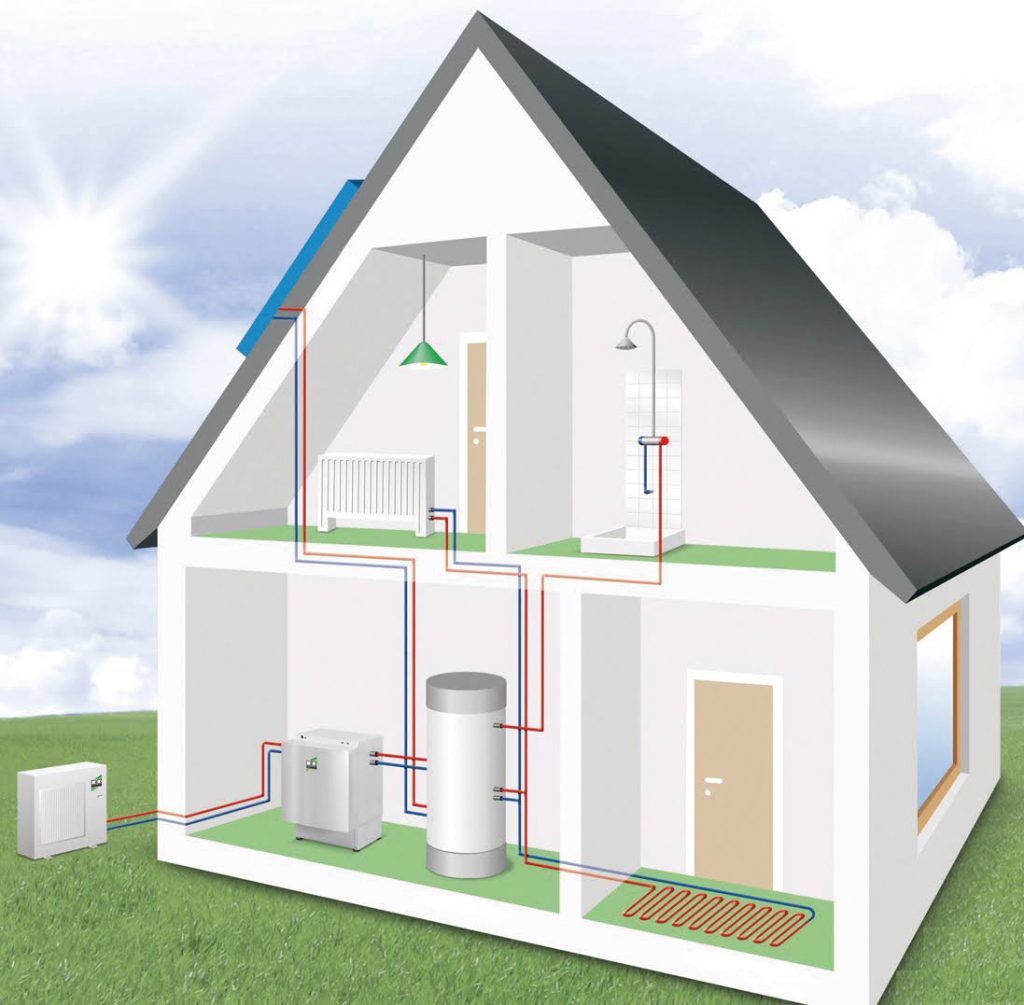

Air to water heat pumps can provide both space heating and domestic hot water. There are two types of air to water heat pumps:

Split systems, as the name implies, has two main components which are split – an outside unit that harnesses the low temperature heat and an inside unit that contains the heat exchanger and heats the water. The outside unit will be smaller and usually quieter than monobloc, which may be a consideration in smaller, urban/suburban sites. Some split systems can also reverse to provide cooling in summer, though it is much better to design your house to avoid the need for mechanical cooling, via overhangs, thermal mass and cross ventilation, for example. Otherwise, you are introducing another carbon burden into your home.

Monobloc systems incorporate both heat capture and heat exchanger functions within a single outside unit, which is thus bigger, but does not take up so much room inside the building. These are cheaper to buy and are easier to install than split systems. Even though split systems come pre plumbed you need an F-gas certified installer for the connection from outside to inside. But the heat pump will need to work harder to heat the water outside and pump it into the house.

Heat pumps are also available that come integrated into the hot water cylinder, though note that these are designed to work most efficiently by scavenging waste air from areas such as kitchens and bathrooms, which would already be targeted by a mechanical ventilation heat recovery system.

Air to air heat pumps are also available which, as the name suggests, use the outside air as the low temperature heat source and supply tempered air into the building. These tend to be used in smaller dwellings or flats and, though very efficient, will not generally produce hot water as well thus in most cases requiring an alternative means of doing this. Air to air heat pumps are also more common in warmer climates as they can readily be used for cooling as well as heating.

Mechanical ventilation heat recovery systems are available with an integrated air to air heat pump. These systems use the ventilation exhaust air as the low temperature heat source for the heat pump, which then boosts the recovered heat in the supply air. This approach is likely to work best in an extremely well insulated and airtight house (such as a passive house) that isn’t any bigger than about 150sqm as the supply air flowrate from the ventilation system will be low, with a correspondingly low heat supply rate.

Sizing

Whereas boilers are available in a huge range of kilowatt (kW) outputs, heat pumps tend to be manufactured in predetermined sizes of say, 8kW, 11kW, 14kW etc. It may be tempting to opt for a smaller output model to reduce capital cost, but this is likely to turn out to be false economy.

Correct sizing of the system is critical. An undersized heat pump may struggle to provide enough heat on the coldest days. If you try to extract too much heat from the low temperature heat source you can end up causing freezing. And running the system at high output for prolonged periods will not yield good efficiency – the system will have to work harder and thus use more energy.

Conversely, an oversized system can also create problems resulting from frequent cycling (on and off) and even overheating in some cases.

A buffer tank can be used to reduce cycling, especially at either end of the heating season. Another advantage of buffer tanks is hydraulic separation between the heat pump circuit and the heating distribution/emitters (radiators or underfloor).

It might sound obvious to many, but do not install the outdoor unit in internal spaces – although you might think it would be advantageous in raising the air temperature, it will restrict airflow and compromise performance.

Fabric first

Heat pumps work best with low flow temperature heating systems, in very well insulated dwellings. That’s what makes them so well suited to new builds.

If you can get the heat loss rate of the dwelling down really low, you will not only be able to size your heat pump much smaller but, also, you will need only to trickle background heat into the dwelling. An existing home with a typical boiler is heated via radiators sized to run at around 70degC.

But the heat pump system will be much most efficient producing water at around 40-45degC, meaning that in the case of an existing home the radiators may need to be replaced with larger ones – even though the fabric insulation can almost always be improved which will help.

If you have underfloor heating this will already run at around 35-40degC

which would be ideal – just as well as you don’t want to go digging up the floors.

Cost

Heat pumps are currently more expensive than the liquid or gaseous fuelled systems we have been used to, but again do not be tempted to save on capital costs by undersizing the system as it may either struggle to heat the house or end up costing more than you expect – or both.

The cost of installing a heat pump can vary widely – it can depend on the manufacturer but most of the cost has to do with sizing (the bigger the house the bigger the size of the heat pump) and how much hot water storage you need. How difficult the installation is will also impact on cost. Get at least three quotes to compare specification and cost, choosing reputable installers.

This will be a prerequisite for grant aiding – on the topic of grant aiding, grants are only available in ROI for existing buildings, see selfbuild.ie for full details. In NI the grant that’s available is only for boiler upgrades (to high efficiency fossil fuel or wood pellet).

In ROI, supplier quotes found online range from €8.5k-€14.5k bracket to €12k-€18k bracket for homes up to 200sqm. And between €15k-€23k for homes up to 500sqm. In NI, the Energy Savings Trust reckons a heat pump installation costs £7k to £13k – presumably for the smaller sized homes.

Installation and maintenance Twenty years ago, a heat pump expert told me that a significant amount of his time back then was spent assessing heat pump installations that had been wrongly sized or installed, or both. Of course, a lot has happened in the world of heat pumps since then, but these remain two key factors.

So, what sorts of installation problems can arise?

Simple electrical issues, faulty wiring for example – use a reputable installer who will install and test the system properly.

Wrong type of refrigerant – it is important to make sure that the refrigerant is suitable for the model of heat pump installed. There are more environmentally friendly refrigerant options available but not all systems can use them.

Poor performance and/or high costs due to wrong sizing (usually undersizing).

Unfavourable location: too close to house (insufficient air circulation); exposed to direct sunlight; too close to planting (leaves can foul grilles/fans and restrict access and airflow); too close to areas likely to be affected by snow drifts (not such an issue in Ireland perhaps).

Coastal locations are not favourable as the salt air corrodes metal surfaces – look for really good quality coating or consider a ground source heat pump instead.

Excessive noise: inadequate mountings, too close to a window, too close to neighbours – if noise is going to be an issue, compare dB rating of different models.

Above all, don’t forget about maintenance. Heat pumps are promoted as the low maintenance option – after all, how often does your fridge need serviced? But a heat pump contains a few more components than a fridge and will need servicing periodically – this is especially true of water source types. Easiest is to sign up to a maintenance contract with your installer.