In this article we cover:

- How to factor in material prices increases into your project

- Current builder’s estimates of the cost per sqm

- Top tips to not go overbudget

- How they tackled the renovation: where to start

- Insulating an existing house: dos and don’ts

- How much insulation is too much insulation

- Window choices for seaside location

- Repairing bay windows

- Rebuilding roof extension due to leaks

- Details of structural supports

- Thrifty kitchen design

- How the design evolved

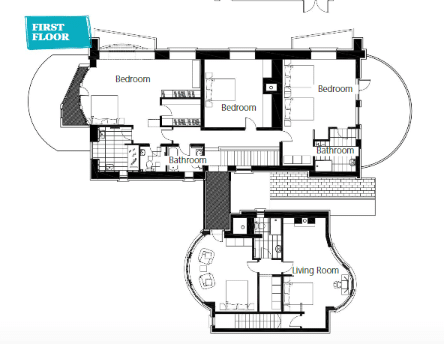

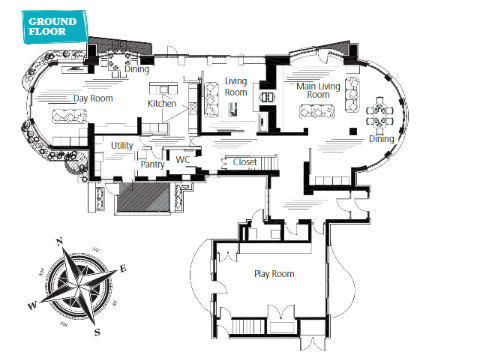

- Floor plans

- Supplier list and professional photographs

“We mostly bought the house for its location and its views, but also because it was spacious enough to accommodate our large family,” says Brian.

“There was a lovely feel to the place and lovely people had been in the home. A big bonus was the fabulous landscaped area – the previous owners were keen gardeners, having planted a hundred different varieties of plants. We’re in a sheltered spot and have a wonderful microclimate here. The wind is prevalent at the front of the house, and we are irrigated by an aquifer.”

With decades’ worth of design and building experience under his belt, Brian had clear ideas of what he wanted to get done. Or so he thought.

“Even though this was mostly a renovation project, there were 35 revisions to the floor plans,” he says. All building projects need a well thought out plan, and Jane and Brian took their time getting it right and choosing which areas to prioritise.

“I then got it all into detailed drawings. I have my own team of tradesmen to call upon, and my dad Bernard also helped out – he’s 70 years old and a talented builder. So the project was in safe hands.”

Repairs

“We lived in the house while we were planning what to do, for about six months. We planned out how to modernise the interior, and also got rid of the pillars at the front. We then lived on a building site for five years. It took a long time because I was chipping away at it in between jobs,” says Brian.

“We quickly realised a lot of the bay windows were letting water in due to poor flashing details. It would happen during bad storms. The bathrooms were leaking too and fell apart pretty much after we bought the house.”

“The tanking on the upper floor just dropped away and water was leaking into the kitchen. Those were big jobs as the plumbing had quite a few joints under the floorboards,” he adds. “I dealt with the joints under floor first, our plumber replaced them with unobstructed pipe runs, then put in underfloor heating and upgraded the heating system from a range to an oil boiler.”

“When we moved in the range was the first thing to go – it was quite inefficient. In five weeks, a tank of oil would be gone. So we got rid of it. Within three months we had a new heating system, which consisted of a condensing oil boiler using the existing radiators. We took apart the range and sold it off; it went towards the price of the kitchen.”

“We couldn’t go for a heat pump as the house didn’t meet the energy efficiency requirements, even though we insulated the attic and pumped the walls with EPS beads. That was the second thing we did. We could have gotten a grant for the insulation but there’s too much paperwork involved, so we didn’t bother.”

“In an ideal world we would have insulated from the outside, as I think that’s the better job, but we couldn’t because of the exposed brick. Considering the relatively low level of workmanship around at the moment, adding insulated plasterboard on the inside leaf is risky in terms of condensation.”

“And unfortunately, at the moment, the low level of workmanship extends to plasterers and finishing work too. Training has been pushed back, partly due to Covid but also because the system is slow in doling it out.”

“In general, I think we are overinsulating houses nowadays – it just adds to the cost. It should be enough to have 250mm in the attic and 100 to 125mm in the floor. All of that extra insulation we’re putting in is not preventing overheating in summer.”

Maximising the views for this seaside renovation in Cork

“Our number one priority was to make the most of where we were, and to prioritise the views,” says Brian. “Living in the house we could see where the sun was hitting the rooms and at what times, which dictated the angles for the windows. The choice of marine grade windows (anodised aluminium) was a good one, with jointless corner details, even though they set us back thousands of euros.”

“They’re high spec, it’s the same ones they use on high rises. It’s a guarantee our windows won’t fade, as that can be an issue because of our exposure. They had to be craned in and we had to add structural supports for the 7.7m slider. We had to get rid of a circular planter first, and at the end replant the beautiful garden after the machinery had gone.”

“All of the units are triple glazed, including the three-part slider, and they give a lovely feel to the house. We roughly kept the same openings.”

“The kitchen was fine when we moved in but it wasn’t facing the way we wanted and it was a bit dated, from the 1990s, in a country style. We wanted to remodel it to take advantage of the views as best we could. We played around with different angles for the undercounter units. We didn’t want any overhead units and to give us more ceiling height we rose the kitchen angled beam into the ceiling void so it would not be seen – myself and my dad did it.”

“Because we don’t have high units, we have storage and larder all in one area, and a pantry. Once we had the design all finalised, we got a flat pack kitchen company to manufacture the parts and we put it together to save on costs.”

“The countertops are quartz and the existing floors white oak – we matched in the new sections to the existing floors which we sanded and polished off.”

Extension

“We had to rebuild the bedroom extension because the roof was leaking. The water was brown from bat excrement and the smell was unbearable,” says Brian. “The bats were nesting in the roof, living in the insulation. They were very small, no larger than a 50c coin. We got a professional in to relocate them to the forest.”

“To rebuild that extension we had to reinforce the joist underneath and I built a timber frame on top of that, insulated with fibreglass; it’s a warm roof construction. On top is a flat roof with pea gravel so when we look out the window, the angle reflects the light and looks like a beach from the bedroom.”

“The original bedroom extended out in a semi-circle but we made it more angular to face the harbour and to maximise light and views.

Current building costs

So as a builder, what does he think of the current increasing in material costs? “You have to build in 15 to 20 per cent up front deposit into large jobs because of the large deposits needed to buy materials now,” says Brian. “That’s the only way I can see any kind of cost certainty, to buy everything when the project starts: block, steel, roof slates, to secure the current price. Booking it in at the start means you won’t get caught with further increases.”

“I priced a job recently for an extension, and the homeowners thought they could get it for €60k to €70k. It was a 35x25ft modern glass type of structure and included PV (solar panels that generate electricity),” says Brian. “I had to price it at €145k and that’s only with seven per cent profit built in, which is what I would put on a small job like that. If you put on 10-15 per cent you would not get the job. It makes building as a profession in this country unsustainable at the moment, made even more difficult because of over regulation, taxation and anti rural planning policies.”

“If I were a considering a self-build, I would wait a year or two to build – it’s impossible to get block layers nowadays and plasterers and electricians are run off their feet. A lot of them are gone abroad and aren’t coming back. If I couldn’t wait, I would add a 15 to 20 per cent contingency to my build cost. Unless you have a fixed price contract, prices will fluctuate and just add to the mortgage.”

“It’s crazy to see that at the moment a builder’s finish is coming in at €225/sqft – before Covid it used to be €125, then it went to €150 at the start of the pandemic and overnight it pushed up to €200-€225.”

He also argues that builders can safely work through the pandemic. “The electrician, then the plumber can be on site when no one else is,” he says. “Then builders are often a pod onto themselves, working together all the time. Builders should be wearing masks and sanitising anyhow.”

Q&A with Brian

What surprised you?

The biggest surprise was the stepped flashing detail being non existent – the external face of the house was wet. We had to go 300 to 400mm down to put in vertical membranes and stepped flashings when we removed the windows.

What would you change?

We spent so much time living in it as we were doing the house, every decision was a considered one. We took our time. And it was more cost effective this way. It was a five year build, fitting it out as I was between jobs, and we’re in seven years now.

Favourite features and biggest splurge?

The panoramic windows, which were also our biggest splurge. We spent about €50k on the windows in total. We knew we would do it only once and it’s the best investment Jane and I made.

Would you do it again?

I would do it again tomorrow. But I wouldn’t let it drag on for so long. It went on and on and there was a lot of dust. It was even in the kids’ cereal in the morning.

I could not have done the project with out the extreme hard work and the quality finish carried out by my dad Bernard O’Regan, Martin O’Regan, Paul Healy, Stan Waltz and Nicky O’Regan. Jane and I are forever grateful to these guys for making our dream home a reality.

Brian’s tips

Work from detailed drawings.

This is key. Everything should be on the drawings, i.e. sockets, lights, vents runs, kitchen appliances, bathroom layouts, drainage, etc.

Keep an eye on site.

Make sure that any change, no matter how small, is written down, priced up and that you’re happy with it and have approved it.

Make decisions before you start the project.

Flooring, tiles, kitchen, bathrooms, etc. Build in the lead times for each – ask each supplier for their timeline and when they will supply items to the site. Ask your tradesmen/builder for a list of what they will need ordered, and if you need to get any materials for them, before they start.

Assume the worst.

In the case of a renovation like ours, assume the worst case scenario: no foundations, no flashings, and the need to rewire and replumb the entire property. Murphy’s Law in a new build is that some things will go wrong so allow three to four months extra as a contingency. There are too many variables to control: delays to delivery, tradesmen not showing up, the building not drying out, a decision you’re struggling to make leading to delays, the bank not signing off on the stage payment, not to mention the weather.

Seaside Renovation in Co Cork Suppliers

Windows

Reynaers Aluminium from West Windows

Kitchen

Daniel O’Donoghue, Cullinview interiors

Bathroom ware

Riva Tiles and Bathrooms

Bathroom Tiles

Tiles Design

Flooring and Tiles

Cork Tile and Flooring

Roof

FibreTech Roofing Ltd.

Plumbing and Heating

Nicky O’Regan

Electrical Contractors

Kinsale Technologies

Spec

Walls

Brick ,water proof membrane,100mm block 100mm cavity pumped 100mm block 65mm insulated plasterboard.