In this article we cover:

- Site hunting with tips to secure planning permission

- Designing a home from scratch and how to save at this early stage

- Building a passive house at the same cost as a regulations compliant house

- How to find an architect and tips for working with one

- Hiring a quantity surveyor and tips for working with one

- Finding a builder who gave tips on saving money throughout the build

- Tips to keep on top of costs

- Site access issues and how they were dealt with

- Why they chose the passive house methodology for the specification

- Specification details and what they would do differently

- Savvy kitchen design tips with cost details

- Troubleshooting

- Heating, hot water and ventilation system choices

- Professional photographs and supplier list

Sometimes the only way to find a site is to see if a local farmer might be open to selling a field. That’s precisely how, after a three year search, Emma Ryan and Kevin Crowley found their dream plot.

We wanted to build in our local area, so we started looking for a site through advertisements and estate agents,” says Emma. “Three years later, we still hadn’t found anything. My dad works in agriculture and he suggested we buy land from a farmer who might not need all of his holding. We started asking around to see if any would be willing to part with some land. That’s how we secured our self-build site.”

“The farmer we approached had one site zoned with planning, another without – the one without is just a mile away from where Kevin grew up. It had lovely views and we loved it, it’s farmland all around. We were told it was the worst area to get planning in, but we still went sale agreed subject to planning. It was a good price for the site.”

Design phase

“I had gone to an engineer to help us with our project, and I had been on the lookout when we were site hunting too. I used to pass by a house under construction and I really liked the style, so I looked up who the architect was; I did the same for another house I fancied and it was him too. It felt like it was meant to be, so we went and spoke with him to see if he would work on our project,” says Emma.

“Gareth took on our project and started by asking us to look online and make a mood board of houses we liked. When we showed him what we’d come up with, he said he rarely saw traditional twee cottages paired up with German black boxes. But Kevin and I are the same, those are the styles we like.”

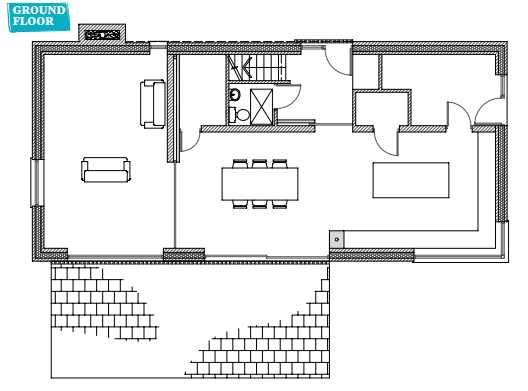

“The solution was to keep the house form very simple, have it nearly look like a converted shed. The design includes a stable at the side (yet to be built) for a traditional courtyard layout. There’s glass at the back of the house to bring the outside in.”

“Gareth said we should use planting and materials like sandstone gravel, to soften the muted colour scheme. We talked about a border between the path and the house because the grey can look stark.”

“In the end, the layout he came up with was bang on what I had mapped out in my head,” adds Emma. “We had two runs to get it exactly how we wanted – a modern take on the traditional farmhouse.”

“When we went for planning permission, we showed the county council our drawings, where our two sets of parents were living and the fact that Kevin’s sister has a disability and we needed to be near,” says Emma.

“It was a struggle to get through to them until I mentioned our architect’s name – then it was a completely different experience. The planner knew of him, as he had won some awards and was well known in the area.”

“In the end we secured planning permission fairly easily and went ahead and got our construction drawings put together.”

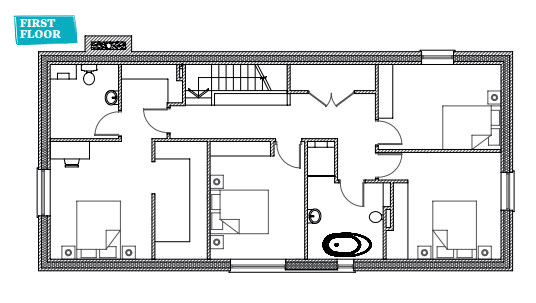

Passive house drawings

“Kevin and I were both in agreement we should spend on the bones of the house so we maxxed out on our windows and invested in insulation,” says Emma.

“The most straightforward way to go about it was to follow the PassivHaus methodology, and we hit all of the targets in terms of airtightness, U-values and we also installed a mechanical ventilation system with heat recovery.”

“We did look into passive house certification, but it would have been €7.5k to get the cert so we told our architect that was the standard we were going for but without the paperwork.”

“After that we hired Karl, a quantity surveyor (QS) that was recommended to us and an engineer to draw up the construction drawings and oversee the build, someone we knew to be obsessed with details and who had experience certifying to the passive house standard.”

“We had already worked out a cost efficient shape with the architect and then the QS specified the best we could get within our budget – he did up the tender alongside the engineer and we went to a few builders he recommended and others we knew from the area. The engineer took on all the health and safety paperwork for us as well.”

“We were able to find cost effective solutions at this stage; for example the engineer suggested changes to knock things, or choose simpler mechanisms. The QS and engineer worked together to find the best solution.”

“One change we made on the inside was for the pocket door – it caused hassle because structural steel is expensive so we changed the length of the opening, reducing it by a foot, even though it does impact on the look to a certain extent.”

“You end up getting so obsessed with details – during the build everyone was driving us mad saying the kitchen window was wrong at two feet above the kitchen sink. We trusted our architect and we are so glad we did – I can see why he did it now that we are living in the house. Because of the height on the site, when you are at the island you have a picture window,” says Emma.

“I have to say that in general I am not a fan of long skinny windows at the front of houses, because I have a thing about symmetry. But in our case with the fireplace, changing the openings would have ruined the look both inside and out.”

“The bottom line is, don’t change architectural details and don’t panic when you’re on site and start changing things because every seemingly small decision will have a knock-on effect. Stick to the plans.”

Build phase

“We didn’t keep our architect Gareth on for the full build, but he gave us some pointers, such as the colour of the windows,” says Emma. “Gareth also told us it shouldn’t cost more to build passive just because builders are afraid of it.”

“Kevin and I work full time and we knew we wouldn’t have the time to oversee the project ourselves, (and even at that our involvement was pushed to the limits!), so we asked builders for prices. The construction drawings and the QS list of items to cost were our tender documents.”

“Some companies came back to us with ridiculous numbers. With costed plans, a lot of builders didn’t want to be involved, I suppose we were taking away their ability to make a profit.”

“Our choice then was to go with a company that had been trading for three years as a builder/quantity surveyor outfit specialising in estates and one-off houses. They made a lot of suggestions to help save on costs.”

“Our first tender was actually for timber frame, simply because we were going low energy. We knew it was going to be a bit more but it was insanely more, about 12 per cent more than a block build, even when taking into account the passive specification.”

“We wanted to have a contingency and we would have had none if we had gone down that route. Everyone had said timber frame made the most sense for our specification but in the long run I’m glad we went with blockwork, the house is soundproofed and our builder was very good, showing great attention to detail.”

“I grew up in a 17th Century house, and when I was 12 my parents extend with a 4ft timber frame studwork construction. The thing I remember the most about it was that you could hear everything. So I didn’t mind too much to do the switch.”

“To make sure the house would keep the heat in, we started with an insulated raft foundation, which has a thick outer ring of EPS boards that click into each other. It was the first time the builder had used it, so he was a bit concerned. We said it to the engineer who then made sure to be on site for the installation, which was a good thing because they had originally put it in upside down.”

“That was thankfully caught in time, but I should have had a grounds person there too to check that the subsoil wouldn’t get mixed in with the topsoil, which is brilliant planting soil. When moving the clay, the diggers mixed it all up. It’s annoying because I can’t do anything about it now.”

“From a practical point of view, the driveway wasn’t wide enough so 30t lorries arriving with stones was an awful pain. We should have made the driveway wider. We also didn’t look at drainage for the garden at this time, even though countless people warned us about planning for the garden early on,” says Emma.

“As for the patio, Gareth told us to leave space for it at the gable end, which is sheltered and westerly facing. As it turned out we put in our patio a bit hastily at the sliding doors, as that felt like the most natural place to have it. But it’s actually not the perfect spot for it when you take into account the prevailing winds.”

“It was a fixed price contract which was finished within the timeframe agreed, subject to the few changes we made but there weren’t too many. We weren’t on site that often, working full time as we did. The contract also included prime cost (PC) sums, or an estimate, for some items like the stairs and kitchen.”

“During the build, we had two guys on site all the time who were dedicated to the project. For security we had a huge old hedge you couldn’t get through plus big security gates. We also have close neighbours, who protected the site by being there.”

Systems

“We knew from friends who had recently self-built that our house would be super warm, and we had no fear of it getting cold. But we still installed an air to water heat pump with underfloor heating everywhere, just to be sure and also to tick the renewables requirement in the building regulations,” says Emma.

“We went with a precast concrete upper floor – pipes for the underfloor had to be laid upstairs and down. The plumber hadn’t factored them in the upstairs part but as it had been specified, he had to put them in.”

“We moved in the winter months, heating the house with our 7kW furnace to 21 degC, it was really cosy,” says Emma.

“It’s so warm the underfloor has kicked in maybe four or five times since we moved in two years ago – looking back on our bills for the first year, the electricity bill including work on the house came to less than €100 per month, keeping the house at a steady 20degC.”

“We now both work from home, and we’ve worked out that it has added about €400 a year to our bills. We also feel we could have made the bathroom downstairs smaller and the gym/office room bigger, but it wasn’t something we could have foreseen.”

“We were aiming for an A building energy rating (BER) and it started getting awkward having put in the stove – the person doing our BER said we could only get an A1 with photovoltaic panels.”

“He had seen so many builds with passive air returns but the energy rating didn’t reflect that. If we were to do it again, we might just get a heat pump that does hot water only, and install the solar PV panels.”

“On the topic of power, we added external plugs at the last minute in addition to a feedback loop which means if we lose power for a few days, we can run a generator for lighting/tv/broadband and fridge/freezer. It won’t be able to run the heat pump or the electric showers. We had a generator for two months, using power tools, so we have it there at the ready in case we do get cut off.”

“For water, we have our own well which we knew of at the start. We didn’t consider a mains connection. It’s pump operated so the generator would power that too.”

“As part of the planning approval, we had to get a packaged system for sewage because our soil is too free draining. At home, my parents had reed beds, which were planted 150 years ago. They always kept the house going, but that wasn’t an option for us.”

Heart of the home

“It was probably the kitchen that commanded most of my attention,” says Emma. “I mapped it out with an interior designer who lives up the road; she specialises in designing spaces for autistic children but also in kitchens. I told her what we wanted – a symmetrical design and a big island.”

“I wanted a pantry too, an adjoining room which we had laid out with the architect. This is where all of the foodstuff is apart from everyday cooking items. Beside the cooker are the pots and pans and ingredients like spices and oils. So the design came together fairly easily then, knowing we would be going open plan.”

“Because the kitchen is on full view, we didn’t want presses high up. We either went full height or just put up shelves. The rest is stored in drawers, such as the delf/utensils/cutlery which are opposite the dishwasher for quick emptying.”

“The big press has the kettle, microwave toaster. The doors are on a concertina to hold the cups, coffee machine, all the breakfast stuff. We just close it over and the kitchen is tidy. All of the baking supplies are in the pantry.”

“This means there’s nothing on the countertop and we have lots of preparation areas. It has to be empty otherwise it would clutter too quickly.”

“We did have to change the layout – I originally wanted to be able to use all of the pantry space (6ftx4ft) and have less presses in the kitchen, but we had to move the waste pipes which ended up in the pantry, as did the heating pipes which was an afterthought, so that gave us less space again.”

“We went for timber on the island as the quartz may have been too clinical with all blue cabinets. A great addition is the open shelving for books under the island where the chairs are.”

“I like to cook and wanted a gas hob, which caused an awful lot of problems to get the airtightness right. We had to get a special fan on the back of the normal overhead extractor. If I had known how much noise it would make, I would have tried getting another overhead fan. There’s a valve and we have to keep it open.”

“And because the house is so well sealed, the slightest bit of heat in the kitchen triggers the heat detectors and the alarm goes off!”

“Even though we had decent budget for it I didn’t want a massive kitchen bill, and in the end we paid 17k for it, the pantry and the utility room fit out. I shopped around a lot; for instance I got the brass handles from China for €400. I had one sent as a sample and showed it to the designer who couldn’t believe the quality.”

“A big saving we made was thanks to the upper storey concrete slabs. The shadow gap lighting was originally going to cost €20k but now that the suspended ceiling is off the upper storey slab it only ended up costing €4k.”

“After that we went for a big narrow dining table, we wanted one that would fit in nicely. It’s 3m long. Then there’s the chaise longue at the right of the sitting room. So there’s room to play around with the configuration and move the TV to the second sitting room for a more formal kitchen/dining set up.”

“We got laminate flooring which works well for the kitchen but was a problem in the sitting room as it started to squeak. The builder said it’s the laminate company’s fault and we never got it sorted. It might have to do with it being where the sliding door is.”

“We actually were going to go with tiles everywhere but had visions of kids falling and banging their heads so said no. But in the long term we are considering polished concrete.” Versatile and adaptable, the house ticks all the boxes for a growing family’s needs.

Follow Kevin and Emma’s journey on Instagram @buildingthecrowleyhomestead

Q&A with Emma

What would you change?

I have no regrets having invested so much in the building fabric, apart from not having installed the brise soleil to shade us from the summer sun at the back. We decided to wait and see how it would go, and as it turns out it is roasting, so it’s something we will definitely do down the line. We could also use an extra panel in the sliders to have an extra window opening to bring in more of a draught.

What are your favourite design features?

The windows. I love the look of the big panels of glass.

What surprised you?

In the ensuite bathroom we had to get a custom piece of glass for the shower. It was shaped glass and large, 1.3m tall, and even though I didn’t think about it much at the time, as that was what I wanted, it apparently shatters more easily if it’s cut to a certain shape and is larger than standard size.

Long story short, it did shatter from a knock. That was quite a shock. It’s toughened safety glass so no one was hurt but it’s not repaired yet. Now I would just make the ensuite a wet room if we could change it. It’s all tiled and tanked anyway so we could do it if we reconfigured it a bit.

Emma’s tips

Cables for outdoor lighting and gates. When you send electricity outside, make sure there are enough cables for lights, sockets and the gate. We had someone come in to give us a quote for an electric gate, and he said we needed two cables and we’d only sent down the one.

Get a lighting plan done. I regret not doing it for downstairs because there’s such a long run of open plan. We have three lights in the centre based on guessing where the furniture would go. But depending on the angle you come in at, it can look a bit like a long row of lights. The spotlights in the kitchen, as recommended by our electrician, do help brighten up the space when cooking in the evenings.

Be on site as much as possible. We had asked our electrician to cable the stairs but he forgot to, and it caused hassle for the fixtures. He made up for it, but we now have extra lights we didn’t want.

You can never have enough storage. We thought we had a ton of storage but if I could, I would double it. We wanted a second fridge in the utility but couldn’t add it because of the need for presses. At the moment the store room is where we keep our DIY tools because we don’t have the shed built but once it is, we will turn the store room into a children’s den.

Costs travel downstream. What had been costed were joists but now that we were block building, we chose precast concrete for the upper storey. The structural cost was similar, but we had to upgrade the floor covering. Kevin insisted on carpets on the landing and in the bedrooms but with the underfloor we were told we needed a special underlay. Kevin left all that fun stuff to me, a challenge when you have monetary constraints! A supplier suggested we get a thick bouncy foam-backed carpet instead, it was better quality and avoided the need for an underlay so that’s what I went for.

Spec

Walls: 200mm full fill cavity with 200mm EPS beads (100mm blocks each side) for U-value of 0.18W/sqmK

Floor: 300mm EPS board on standard build up for U-value of 0.1 W/sqmK

Roof: pitched roof insulated on rafter (warm roof) 175mm mineral wool with insulated plasterboard underside for U-value of 0.15W/sqmK; pitched roof insulated on ceiling (cold roof) with 400mm mineral woold for U-value of 0.11W/sqmK; former flat roof U-value 0.14 W/sqmK

Energy Efficient New Build in Co Cork Suppliers

Architect

Simply Architecture, simplyarchitecture.ie

Engineer

Hilliard Tanner of TSD engineering, tsd.ie

Quantity surveyor

Karl Slyne

Foundations

Supergrund, kingspan.com

Windows

Rationel, rationel.ie

Builder

Hurley and White, Dunmanway

Kitchen

Cullen View Interiors, cullenviewinteriors.com

Sanitaryware

Bathshack, bathshack.ie

Cast iron bath

Kilkenny Architectural Salvage, eurosalve.com

Furniture

Couch from Finline Furniture, rugs from sostrenegrene.com and kukoon, soft furnishings Home Sense and Dunnes Stores

Photography

Mike O’Leary, greengrafphotography.com