In this article we cover:

- Main aspects influencing the design

- Planning permission process

- How the project was managed: Hiring a foreman

- What the day to day was like on site

- How the house was built

- Heating and hot water systems

- Details of the concrete interior finishes

- Top tips for the perfect finish

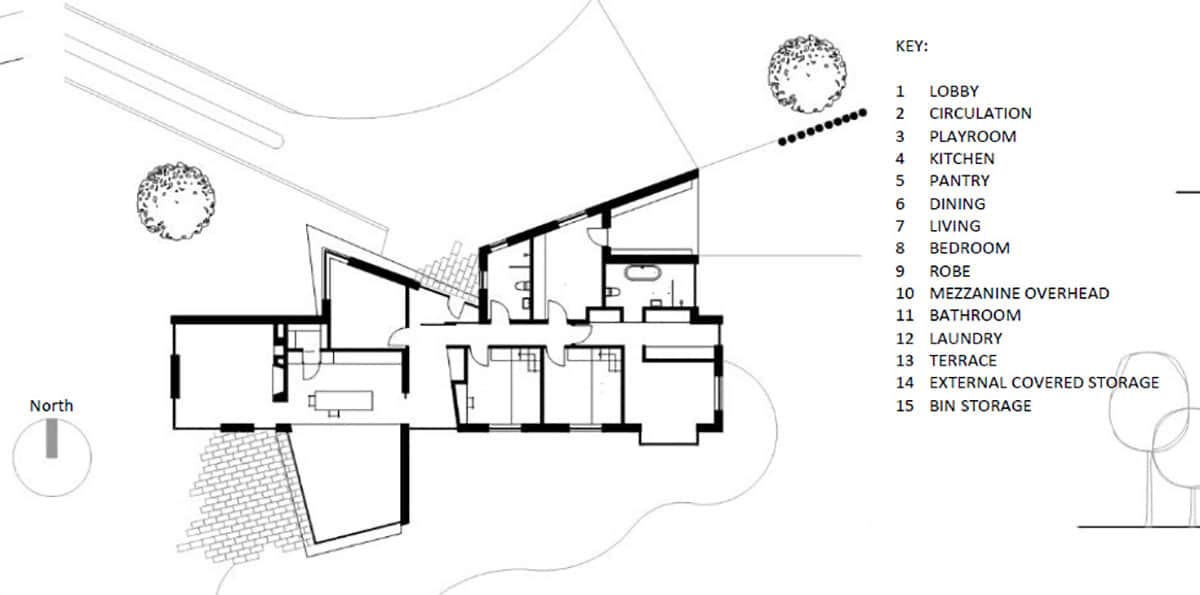

- Professional photographs and floor plans

- Supplier list

How did the project come about?

The process was the same as for any project I take on; we had a list of things we wanted out of the house and a specific location in which to put it.

The choice between traditional and modern is a question of taste but also rooted in the features of the land, such as orientation, views, overlooking, overshadowing, rural vs urban, exposed sensitive landscape, etc.

This site is located within an agricultural setting, backing onto the edge of a mature forest. For this reason the house is clad in deep green corrugated metal sheeting to reflect the farm sheds scattered about the landscape, but with crisp modern and highly detailed finishes and junctions.

Was planning permission hard to get?

My research had shown that a couple of planning applications for traditional bungalows with white plastered walls had been refused on the road due to the elevated nature of the sites and the visual prominence of the area from a busy national road passing about 700m south of where we planned to build.

Once I realised that, I knew that the only successful solution to a house in this location would be to effectively make it disappear from that southerly aspect and main road.

How was the project managed and built?

Separating my business office, a log clad steel shipping container, out of the house and building it before we started building our own house was one of the best decisions I made on the project.

It meant that I was running my day to day business from the building site and should any problems or queries arise it was a short walk across the site to resolve the issue and keep the momentum going.

I knew that I needed someone I could trust to help with the running of some of the day to day management of trades and also have someone to bounce some technical details off for those times you are so immersed in the decision making you can’t see obvious alternatives.

That foreman job could only have been given to one person, a local carpenter who takes a lot of care and pride in his work. I couldn’t think of anyone better to help us.

How did you go about hiring your foreman?

I first approached Declan about the possibility of helping to build the house about a year before we broke ground so we could review the method of build together and highlight any issues that could possibly crop up. We know each other very well and I trusted him.

Unlike others who turn up in the morning, do their own job and go home, Declan is always interested in how he can do his job to make it easier on the next trade. You don’t get that attention to detail from everyone. Our arrangement was verbal; he kept track of his time and I paid him by the hour.

What construction method did you choose?

The house is built on a passive insulated slab. Declan had no experience with this type of foundation system but as a carpenter had all the necessary skill and attention to detail to tackle it.

A lot of attention had to be given to the setting out of the passive slab; the width of every window and door was set on this grid to suit the width of a corrugated metal sheet therefore eliminating the need for any cutting and waste on site. Openings are either one, two or three corrugated sheets wide and this had to be factored in from day one.

Aside from the perimeter thickening for the external walls where the insulation thickness was 200mm, the thickness of the floor slab insulation for the majority of the floor was 325mm.

For continuity of the external envelope and to eliminate thermal bridges, the walls and roofs were insulated externally. Similarly, the roofs are constructed as warm roofs, again avoiding any thermal bridges.

External finishes are kept to a simple palette of two: corrugated metal and timber. The walls and roof of the main rectangular block are clad in a deep green corrugated metal cladding while the ‘pop outs’ to the north and south of the main block are clad in two different methods. The first is a waney edge rough ship-lapped timber board with the bark adhered to it, giving the building a rustic look and tying it into its forest roots. The second method consists of vertical prepared timber latts in a hit and miss pattern, again to reflect the forest setting.

What did you do for heat and hot water?

The strategy from the outset was to insulate and make the house airtight to the highest standard possible to eliminate the need for space heating as much as possible.

The original intention was to fit a small gas boiler to provide hot water as the thermal mass and heat gain attained during the day would provide the little heat needed during the winter months along with the stove in the main living space.

However, when we analysed the cost, there really wasn’t much difference in the cost of installing a small air to water heat pump against the gas boiler and submerged tank option, about €1,500 to €2,000. That excludes the underfloor heating pipes as I had them in already as a ‘just in case’. This is comparing the heat pump system itself with the gas boiler, insulated cylinder, submerged LPG tank, ground works, etc.

So, we installed the heat pump and as expected it’s being used predominantly to heat our domestic hot water; the space heating is very seldom called upon. We installed a heat recovery ventilation system to circulate fresh air and again the heat recovery function is on bypass most of the year.

My overall energy bills for the house for a year are about €800. Over the past 18 months or so, the space heating (underfloor heating) typically kicks in for the north facing playroom and bathroom in early December for about an hour in the morning. This heat is required for these spaces alone until the beginning of March and after that the heating is not called upon again, unless we experience a cold snap.

Concrete interiors

Concrete floor

The 100mm polished concrete floor throughout the entrance, circulation and main living spaces allow for a seamless flow from the main door to the public spaces. The polished concrete floor acts as a thermal mass, storing the heat from the sun during the day.

Concrete chimney

The tactile, board marked concrete chimney breast provides thermal mass and divides the kitchen/dining area from the living room. The thermal bridge at the roof junction was tricky as was the detailing of the formwork, sandblasting of the timber lining boards, etc. Close collaboration and consultation with the engineers and tradesmen on this was crucial. The 7.5kW stove isn’t turned on very often but when it is, a low amount of fuel keeps it ticking over without it getting too hot.

Kitchen island

The formwork/mould, (a flexible, curved hardboard template), was made in the field when the passive slab was being laid. It was built on its side (Declan’s idea) and the concrete was poured from the narrow 60mm edge at the top, on the same day as the main floor was being laid (to get the exact same mix). A pencil poker vibrated the concrete. The structure was left protected in the corner of the field for another six months until the roof was on. Andrew hired someone with lifting equipment to transport it, still in its formwork to maintain its strength, into the dining area. Heavy lifting by family and friends rotated and set it into place. The construction of the shutter and pouring of the island cost about €1,800; grinding and polishing around €1,500. That excludes the design time that went into it for both Andrew’s time and the structural engineer’s.

Andrew’s tips

Consider not managing the project yourself. If you plan to project manage your self-build yourself, know that it represents an immense workload. Being in the industry, I had the skill, knowledge and contacts to make the process a little easier yet hiring a foreman was the best decision I made. Especially if the building industry is new to you, hiring a project manager or site foreman to give some advice and steer decisions can save a lot of stress.

Attention to detail in the construction drawings will make all the difference. A house with the right finishing touches can look and feel vastly different to the same house where these have not been considered. If you don’t have the knowledge or skill in this area, it can be invaluable to spend a little to get the correct advice and direction. For example, the children’s bedrooms are functional with space borrowed from what would otherwise be unused attic area, by creating a vaulted ceiling and a mezzanine play space above the beds.

Plan things well in advance. Making changes last minute costs money so try to forward plan as much as you can.

Suppliers

Architect

Andrew O’Brien Architects Ltd, mobile 086 0730113

Structural engineer

Lenihan Consulting Engineers, Kanturk, CoCork, tel. 029 20900

Site foreman / carpenter

Declan Devoy, mobile 087 2451764

Plumber

Plumbtech, Midleton, Co Cork, tel. 021 463 2469

Stove

7.5kW Jøtul 305, jotuluk.com

Polished concrete floor

Renobuild, Wexford, tel. 053 936 6444

Heat pump

Daikin, daikin.ie

Electrician

Seamus O’Farrell Electrical,

mobile 086 8846545

Air-tightness materials

Ecological Building Systems

Wall and corrugated roof insulation

Insulation, kingspaninsulation.com

Airtightness contractor

Shane Kavanagh, mobile 0879693451

Ventilation

Aerhaus, Dungarvan, Co Waterford, tel. 058 20005

Windows and doors

Triple glazed aluclad timber windows Viking, aluminium windows Reynears, both types sourced from West Building Products, Carrigaline, Co Cork,

tel. 021 4372929

Groundworks

Kennedy Plant Hire, Co Cork

Structural steel

Vaughan Engineering, Kanturk, Co Cork

Passive slab insulation

325mm passive EPS slab by KORE, kore-system.com

Board marked concrete chimney

Millform Construction, Co Cork, mobile 087 239 9717

Stainless steel chimney flashings

Independent Engineering Services, Co Cork, tel. 021 4636638

Aluminium flashings

AMS, Little Island, Cork, tel. 021 4705100

Corrugated cladding suppliers

Duggan Steel, Kilkenny, tel. 056 772 5050

Corrugated cladding contractor

James Mulcahy, Co Cork

Waney edge timber boards

John McCarthy Timber Merchant, Co Cork

Prepared timber latts

Sheehan Sawmills, Co Tipperary, tel. 052 746 7249

Zinc roofs

Pat O’Leary Coppersmith, mobile 086 833 4120

Single ply roofs

Corrugated roof Bauder bituthene fully adhered vapour barrier. uPVC roof Bauder Thermofol U15 PVC Membrane roof finish mechanically fixed to 200mm Bauder PIR Insulation, Bauder bituthene fully adhered vapour barrier. Bauder membranes installed by AF Roofing, Youghal, tel. 024 94632

Internal sliding doors

Cloghroe Joinery, Ballincollig, Co Cork, tel. 021 4873940

Paint suppliers

Pat Walsh Paints, Midleton

Timber glulam beams

Cederlan Limited, tel. 021 496 5233

Photography

F22 Photography, f22photography.ie