In this article we cover:

- House hunting and how the design evolved

- Dealing with an existing planning application

- Demolition work

- Hiring a builder

- Choosing cost effective finishes

- Examples of swaps to save costs

- Heating and ventilation, window choices

- Kitchen and bathrooms

- Garden design

- Timeline and top tips

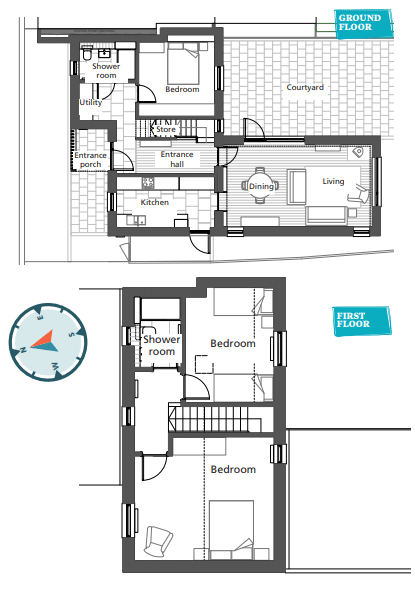

- Specifications and floor plans

- Supplier list and professional photographs

How did the project come about?

After living in the countryside near Dromore for several years I was looking to downsize to a new home that would be more manageable for me on my own. I have always lived in bungalows and being conscious that I needed to plan for the future, I wanted a ground floor bedroom and bathroom.

I also ideally wanted to be within walking distance to shops and have small sunny outdoor space. It was also important to have enough space for family to stay when they visited and I wanted a living/dining space that could comfortably host visitors rather than a small living room and kitchen/ diner which seems to be typical of most smaller houses.

House size: 122 sqm

Plot size: 265 sqm

Bedrooms: 3

Build cost: £185k including demolition of existing cottage, all fittings, finishes and landscaping

EPC (SAP): B (82)

After looking at several properties and not finding anything that was suitable, I found a small dilapidated cottage for sale in a perfect location, the site already had planning permission for a replacement dwelling and I was able to ask my daughter and son-in-law, Susan and Güido, who have their own architecture practice to design me a house to suit my brief.

It was very special to have my daughter design a house for me. We first looked at the site in December 2020 and that Christmas she gave me a lovely architecture book called “A House for my Mother” and now I’m delighted to have my own bespoke home.

What were the first steps after finalising the design?

The existing planning permission was for a larger dwelling than I needed so Susan was confident that a more modest scheme would be approved but due to Covid we were uncertain how long the process could take. Our planning application was submitted just before the first Covid lockdown.

Thankfully we were able to develop the detailed design and construction drawings, and get Building Control approval during the planning process. That meant construction started on site almost immediately after gaining planning permission.

Although there had already been a house on the site we needed completely new services including a new below ground electrical connection, new mains drainage and gas supply. I was very glad that I had Susan to deal with these issues as these all proved to be more complicated to organise than first thought.

How did the demolition work go?

The two biggest issues that arose were actually due to the existing single storey cottage on the site. Prior to starting work, we had to get a specialist company to remove the existing soffit boards as they contained asbestos.

Then, when demolition started, the builder discovered the attached two storey modern property had not been built independently as originally thought and that some parts of the external leaf of the adjoining wall had been built up from the original stone wall of the cottage.

The structural engineer had to agree a solution with Building Control and we ended up needing to retain and underpin the stone wall whilst also building a new cavity wall to allow the new cottage to be structurally independent.

How did you get your new house built?

We worked with a local builder who had been recommended to us and we decided on traditional construction methods which they were familiar with.

The concrete block cavity walls have traditional sand and cement external render that is painted white with a grey base that follows the height of the ground floor concrete window cills. The roof is profiled fibre cement sheets which is more commonly used on agricultural buildings and was very conomical.

The windows and doors and composite timber and aluminium door are high spec. It was the biggest spend and it was definitely worth it; the green external colour really adds character.

I had a modest budget and was guided by Susan who chose a simple palette of materials and selected products that were available during the shortages and delays caused by the pandemic.

A traditional contract was used for the main parts of the build and Susan managed the procurement and installation of the windows, doors, all internal finishes and fittings and new services.

Any hiccups or changes?

Our builder was good, but he was quite traditional and liked to do things his own way. Susan had everything drawn very carefully and sometimes the builders on site didn’t follow the drawings which was incredibly frustrating.

For example, elements such the lintels for the tall doors in the living space had to be moved up and other things weren’t as precisely done as Susan would have liked, and had to be redone or the plans adjusted to suit.

The original design included an external chimney which would have looked lovely but unfortunately to make some savings we had to opt for a metal flue. We also used uPVC rainwater goods rather than aluminium to reduce costs. The build did take longer than we anticipated but I think looking back and considering it was built during the Covid pandemic that it all worked out OK in the end.

What did you do for space heating and hot water?How about ventilation?

The heating and hot water are provided by a gas combination boiler with underfloor heating on the ground floor. I have radiators on the first floor but I really only need to switch these on when I have visitors staying.

Susan and Güido did consider more efficient energy options such as an air source heat pump and solar panels but unfortunately these weren’t feasible due to the budget. The lack of grants in Northern Ireland for these environmentally preferable options is very frustrating.

For fresh air the house has Positive Input Ventilation (PIV) and Mechanical Extract Ventilation (MEV) to control humidity. The units are located in the loft space above the smaller upstairs bedroom and have proved to be very effective.

How did you choose furniture and fittings?

I wanted the interior spaces to be bright and modern and had very specific requirements as I wanted to be able to use my existing furniture which included a 1960s dining table and sideboard and coloured glass pendants that I had always had in our home.

One of my sons is a lighting designer and he was able to help us source similar black fittings to complement my original lights.

The wall hung bathroom fittings and concealed toilet cisterns make the bathrooms very easy to keep clean and I really like the fine edge to the designer sink we used.

We had an amazing kitchen fitter who installed our flat pack units. I would love to recommend him, but he now builds theatre sets. The quartz worktops, oak shelf and tiled splashback make the kitchen feel bespoke even though the items were bought off the shelf.

The timber flooring and tiling were all installed by local companies and the coloured terrazzo style tiles add a fun pop of colour.

Tell us about the garden.

The garden is very simple and low maintenance, the best part is that the design creates a sheltered south facing courtyard that is very private and I still have some green space to look out on through the picture window at the end of the living room.

What would you change?

I love my new home and everyone who visits loves it too, I don’t think I would change anything. The use of the space is very clever, efficient and practical. For example, I didn’t have space for a separate utility room. Instead, the cupboards in the hall contain the washing machine, tumble dryer, ironing board, vacuum cleaner etc.

I really like the wood burner which is angled to sit in the corner and the pocket door to the kitchen that sits discretely within built in shelving.

The large volume of living/dining room space is perfect for entertaining and feels very generous, and is a surprising contrast to the cottage character that the house has on the street.

The thought that has gone into the position and size of all the openings to ensure that the space is always bright and the way the light changes during the day is definitely my favourite feature.

Top Tip

Trust your architect. I know I am biased because my daughter was my architect but it’s so important to hire a professional you can rely on. There were some elements of the design I wasn’t initially sure about when I looked at the plans; for example, I was concerned that the kitchen and hall would be too narrow but they work perfectly. I was very lucky to have Susan and Guido managing every step of the project, everything was planned very carefully and their eye for detail ensured that it got built (more or less!) as we envisaged.

Spec

Floor: tiles/timber floor finish, 70 screed with underfloor heating, vapour control layer, 80 PIR insulation, DPM/radon barrier, 150 reinforced concrete slab, U-value 0.14 W/sqmK

Walls: concrete blockwork cavity construction, plastered finish 100/140 inner blockwork leaf, 150 cavity with EPS bead insulation, 100 external leaf with sand cement render, U-value 0.2 W/sqmK

Roof: warm roof build up, vapour control plasterboard, 147 x 47 C24 rafters, 75 insulation between and above rafters, underlay, battens and counter battens, profiled fibre cement sheet, U-value 0.15 W/ sqmK~

Glazing: double glazed, argon filled, low-E, overall U-value 1.23 W/sqmK

Airtightness: 3.1 m3/h.sqm

Suppliers

Architect

Studio Vericat, studiovericat.com

Structural Engineer

Haworth McCall, haworthmccall.co.uk

Timber flooring supply and fit

WFS Flooring & Tiles, Banbridge, wfsni.com

Tiler

RP Tiling, Ryan Paxton, mobile 07540774255

Decorator

Mac Decorators, Banbridge, macdecorators.co.uk

Stove

Jotul stove supplied and fitted by Boyhill Cookers & Stoves, Lisnaskea, BoyhillCookers.com

Kitchen units

IKEA

Kitchen worktops

Suprastone quartz worktops by Mid Ulster Granite, Lurgan, midulstergranite.com

Bathroom fittings

Sykes Interiors, sykesinteriors.com

Designer sink

Laufen

Windows and doors supply and fit

Rationel, rationel.ie

Ventilation

Envirovent PIV and MEV supplied and fitted by Condensation Solutions, condensationsolutions.co.uk

Fibre cement sheet (roof)

Tegral Profile 6R

Photography

Elyse Kennedy, elysekennedy.com