New build homes are now being built to be as airtight as possible. Increased insulation and double or triple glazed windows are key for keeping the heat in, but they prevent adequate ventilation.

Inadequate ventilation can lead to poor indoor air quality, condensation, mould, musty smells, and excessive carbon dioxide in the home. It can also exacerbate symptoms of respiratory conditions, such as asthma and allergies.

Installing an MVHR system is essential to letting an airtight home breathe while maintaining a high level of energy efficiency.

How Does MVHR Work?

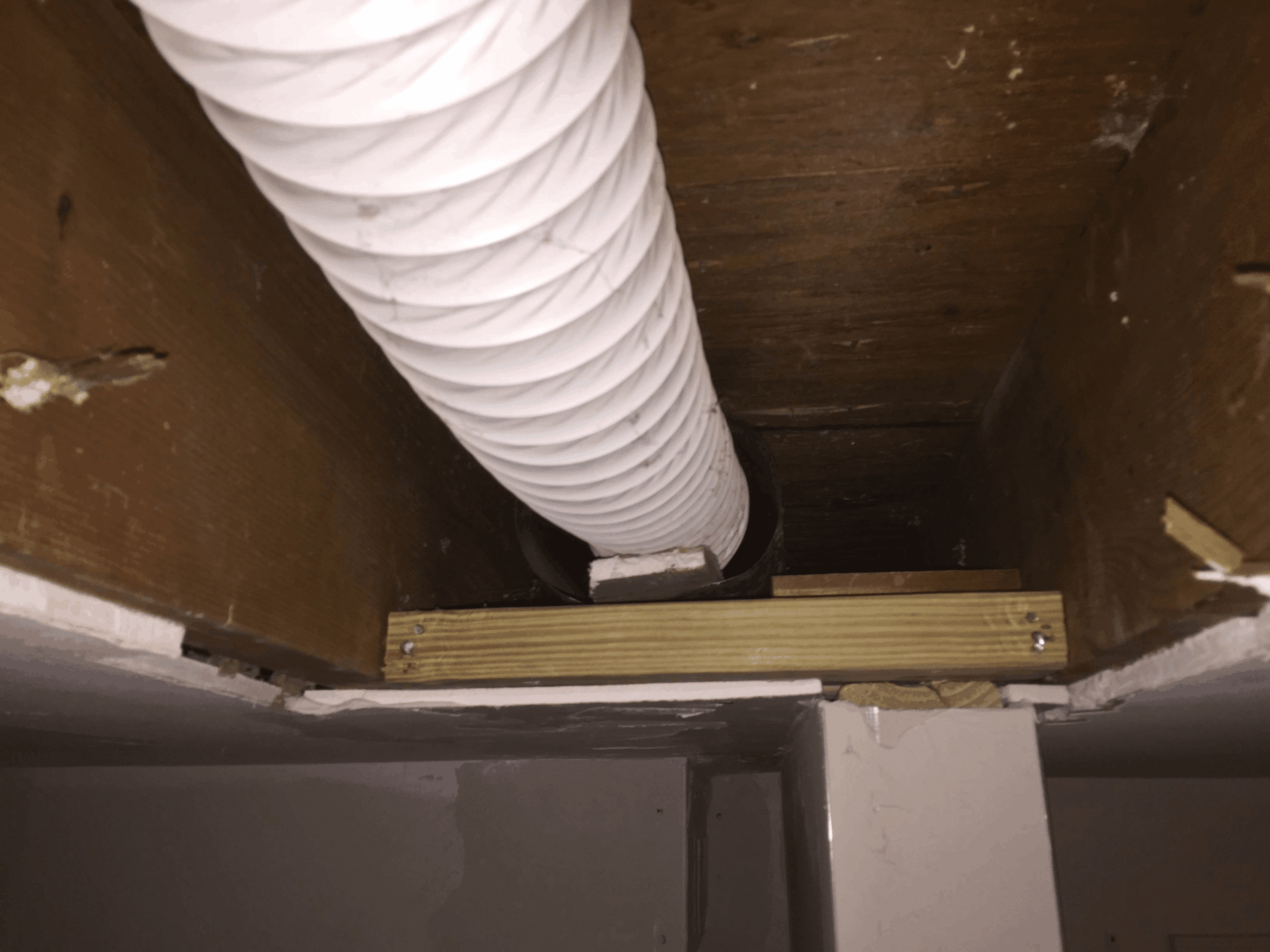

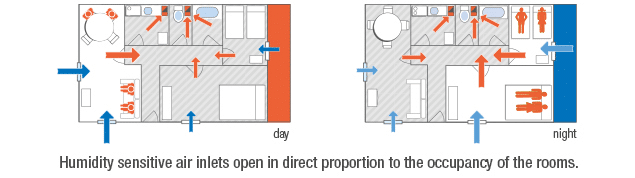

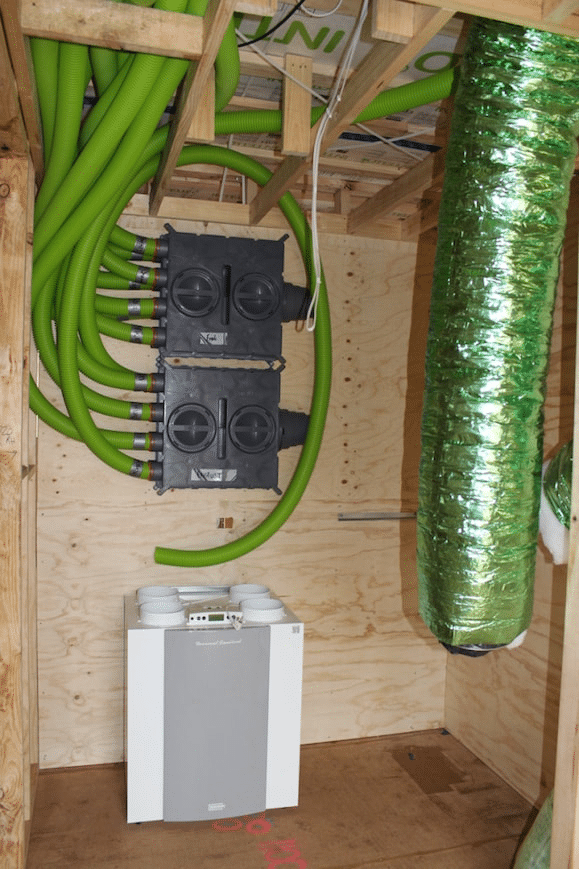

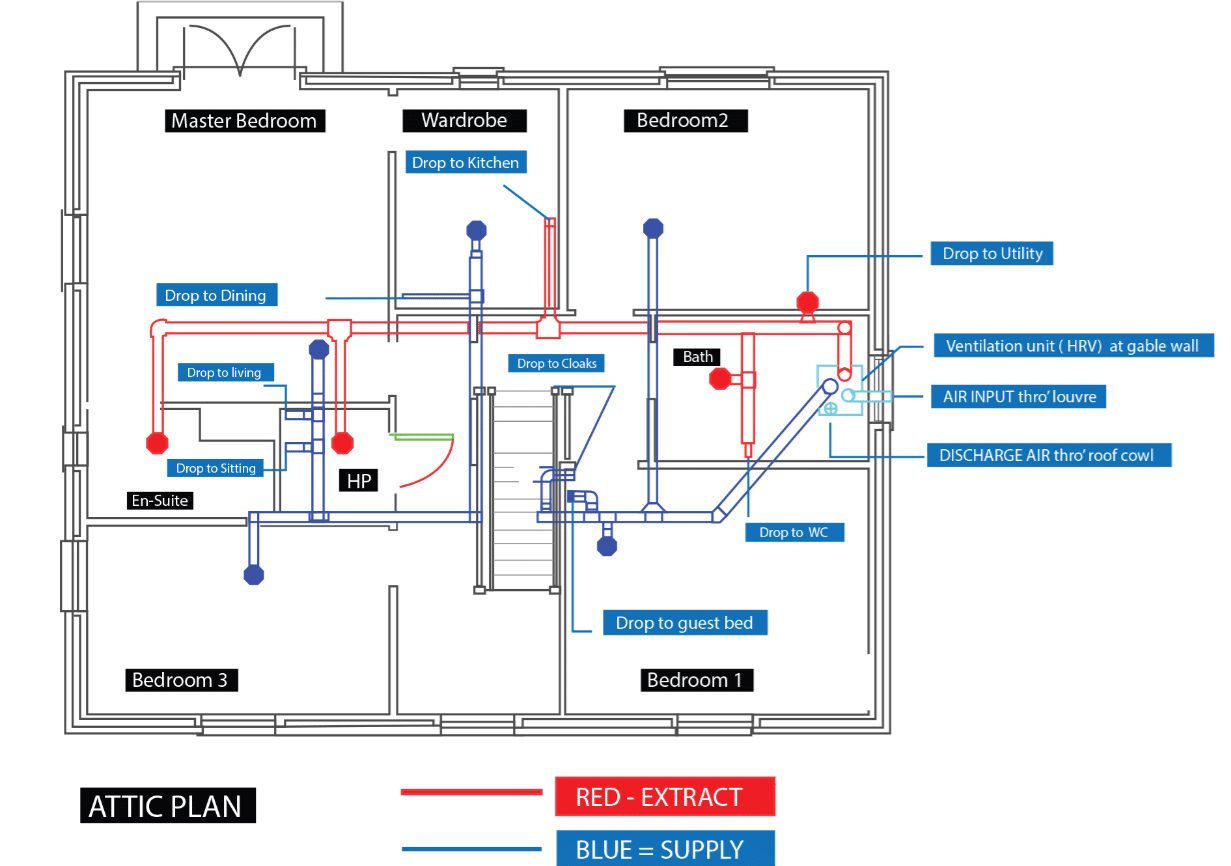

The MVHR unit (usually located in the utility / plant room / hotpress or roof space) continuously draws in fresh air from outside and filters it to remove any pollutants.

Simultaneously, moist, stale, warm air from wetrooms such as bathrooms and kitchens, is extracted and filtered back through the unit.

Both airflows pass through a heat exchanger where heat is transferred from the extracted air to the incoming air. The fresh, filtered, warmed air is then distributed throughout the home.

Benefits of MVHR

The benefits of MVHR are unrivalled when compared to traditional methods of ventilation. BEAM’s award-winning MVHR systems improve indoor air quality while recovering up to 95 per cent of heat that is normally lost through other ventilation methods such as open windows, trickle vents and extractor fans. Other benefits include:

- Reduces condensation & mould.

- Alleviates symptoms for asthma & allergy sufferers.

- Contributes to the energy efficiency of the home.

- Removes musty odours.

- No need for draughty trickle vents and noisy extractor fans.

- Quiet in operation.

- Aids radon dispersion.

Installation of an MVHR System

The key to ensuring you get the most out of your MVHR system is through careful consideration to the design and choice of installation materials. BEAM follows industry best practice and use rigid, large diameter ducting to provide low resistance to airflow and greater heat efficiency. This also helps to reduce noise and running costs.

The ducting for an MVHR system is usually installed during the first fix stage of a build, before any plastering has taken place and below the concrete slab.

For a timber frame house, ducting will need to be installed before the partition walls and floors are plasterboarded. The high-quality rigid ducting that BEAM uses during installation is resistant to crush damage during construction and therefore can be cleaned and maintained if required.

Once the second fix stage of the build is complete, the ventilation unit can be suspended and connected. A fully qualified BEAM engineer will also commission the system, testing the airflow rates and system balancing.

Although installation of an MVHR system doesn’t take place until later in the building process, it is a good idea to plan your ventilation strategy early in the planning stages to ensure appropriate space is available for the unit and ducting.

How BEAM Can Help

BEAM has over 45 years’ experience providing clean indoor air for homes throughout Ireland. All MVHR Systems from BEAM are designed by an experienced technical team and are installed and commissioned by BEAM engineers or their countrywide network of Approved Distributor Partners.

Alternatively, if you wish to install a BEAM system on a DIY basis, BEAM provides design layout, commissioning, and support throughout the installation.

For more information, advice, or a quotation, contact BEAM on +44 (0)28 7963 2424 or email [email protected]