Installing a Mechanical Ventilation with Heat Recovery (MVHR) system in your home is an investment in your personal health and the quality of air in your home.

If you want to achieve the maximum benefits of an MVHR System, it’s critical the system is installed correctly using best practice materials and procedures.

A Mechanical Ventilation with Heat Recovery system consists of 3 elements:

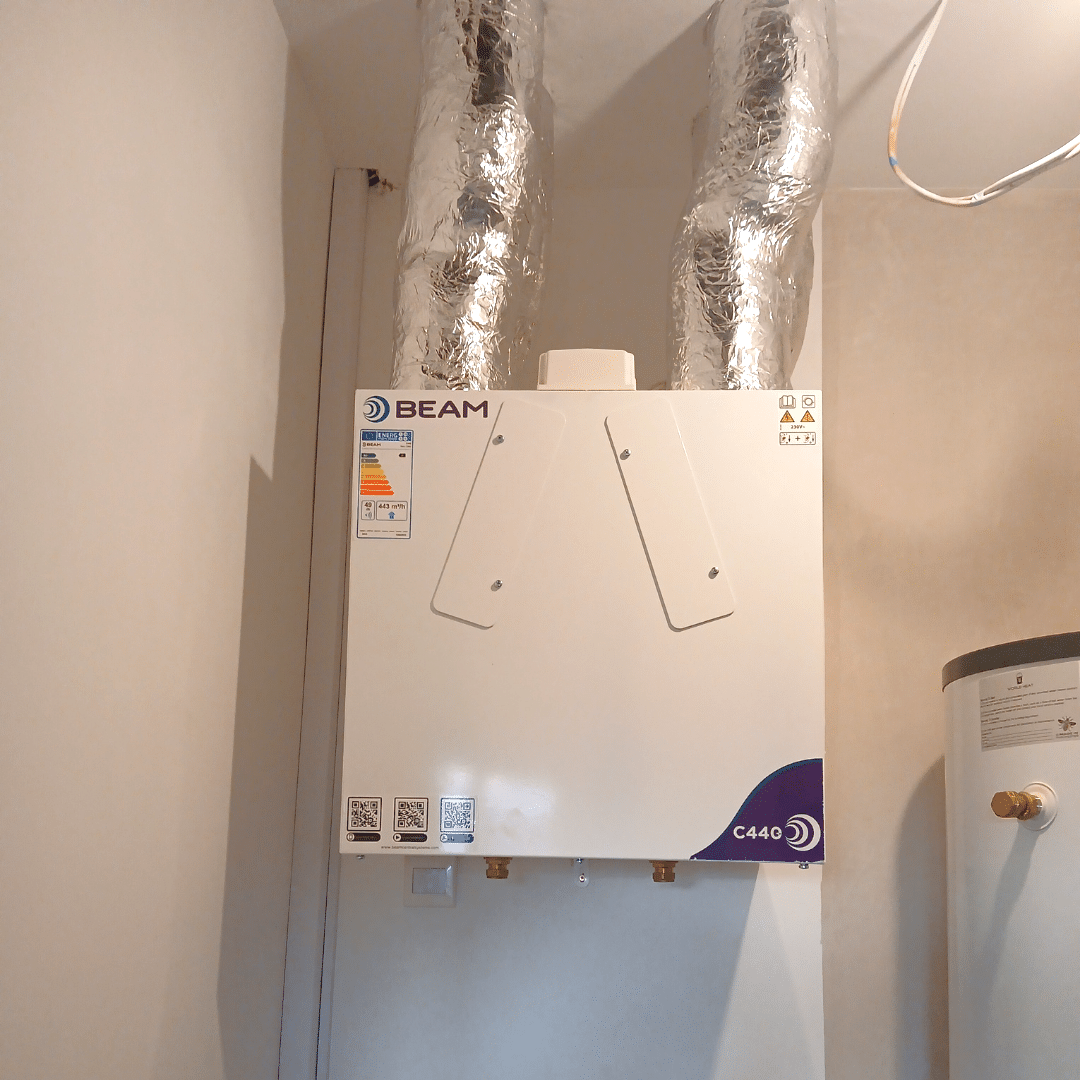

- the ventilation unit usually located in the loft, hot-press, utility room or plant room

- a network of ductwork

- supply and extraction ceiling valves in each habitable room

One of the most important aspects of a well-planned, low energy, highly efficient MVHR system is the ducting type, design and the quality of installation. In this article, we consider important aspects of MVHR ducting and what the recommended solutions and procedures are.

Mechanical Ventilation with Heat Recovery (MVHR) – Best Practice

Building Research Establishment (BRE) recommends a ‘Branch’ type of ducting system as industry best practice. This type of system involves a supply duct and an extract duct coming from the MVHR unit, which goes through the property with a separate duct branching off into each room or area where a supply or extract valve is required.

This type of ducting system allows for excellent airflow rates which will contribute to the overall performance of the system.

The Optimal Size of Ducting Used

The size of ducting used for the installation of an MVHR system will depend on factors such as the required airflow. Ducts connected to the unit will usually come in industry standard diameters of either 125mm, 150mm, 200mm or 250mm, the size dependent on the unit being used. In general, the larger and more powerful the unit, the larger the ducting to allow for adequate airflow throughout the system.

As the ducts branch off towards each vent the size of ducting will decrease. For example, where the initial duct is servicing all valves, it may have a 250mm diameter, which may then reduce to 150mm where it branches off to service a single valve.

Small diameter, semi-rigid radial ducting may be used in MVHR installations with minimal space available. Radial ducting has a diameter of 75-90mm and can easily fit into small ceiling voids. However, to ensure sufficient airflow rates, this ducting should only be used in short runs and should be doubled after 7 metres to meet required ventilation rates. It is also important that radial ducting is properly installed, strapped and insulated in cold spaces to meet Building Regulations.

In some cases, rectangular shaped ducting can be used, known as flat channel ducting. This may be used in areas where space is an issue, such as within the ceiling void.

What Materials Should Your Ducting Be Made From?

The materials used for your ducting is critical for the performance of the MVHR. BRE considers large smooth flow rigid ducting the most efficient way to move air. This is pipework made from solid plastic or metal with a smooth inner surface. Solid smooth flow ducting can offer the following benefits:

- Provides a higher heat efficiency

- Low-pressure loss resulting in low energy use

- Efficient low velocity producing less noise

- Resistant to crush damage

- Easily cleaned and maintained

It is essential that any ducting installed outside of the thermal envelope of the home is properly insulated to retain high heat efficiency and avoid condensation forming in the ductwork.

Commissioning Your MVHR System

No matter the MVHR system or ducting type you choose to install in your home, it is essential that the system is fully tested, balanced and commissioned by a professional. This is required by Building Control to verify the system is operating as it was designed to.

During commissioning, a qualified person will adjust fan speed and airflow rates to ensure the best system performance and the least noise possible. If airflow rates are too high, the system can be noisy, but if they are too low, the system will not comply with ventilation regulations.

How BEAM Can Help

The overall performance of any MVHR system can depend on the type and size of the ducting used. All BEAM systems are designed by an experienced technical team and are installed by BEAM Engineers or their nationwide Distributors/Installers. BEAM offer the highest standards of installation, using only precision engineered metal and plastic solid smooth flow rigid ducting where possible. A minimum of 25mm aluminium foil backed wool insulation is applied to the ducting in all cold spaces and all ducts are triple sealed (glued, screwed and taped) to ensure no loss of air. BEAM also provide full commissioning and certification.

Should you decide to install a BEAM MVHR system on a DIY basis, BEAM provide design layout, commissioning and support throughout the installation.

Contact BEAM for more information or a free, no obligation quotation.