When Denise and Matt got married over a decade ago they set up their base on Matt’s family agricultural holdings, and lived in the farmhouse that had been on the land for over 100 years. The couple carried out an energy upgrade by adding insulation and solar thermal panels. But to make it really work as a functioning family home, they knew they needed to do some substantial work. “The house was cosy and warm for us but it was pretty dark because the windows were quite low,” explains Denise.

They already knew an engineer who did architectural design so they contacted him to help with the overhaul. “A driving force behind the renovation was to turn it into a family home, we had two kids at the time,” says Denise. “Chatting about the project we realised how nervous we were about being so close to the farm, as soon as the children would get out the door they were in close proximity to the livestock and to the machinery.

My heart would skip a beat if I realised they’d made their way outside.”

[powerkit_collapsibles]

[powerkit_collapsible title=”SIZES” opened=”true”]

Plot size: ¾ of an acre

House size: 3,100 sqft

[/powerkit_collapsible]

[powerkit_collapsible title=”BUILD SPEC”]

Floor 200mm hardcore under 150mm C35 concrete under radon barrier under 150mm polyurethane insulation under 75mm screed, masonry wall blocks laid on flat left exposed and insulated externally with 120mm rigid thermoset phenolic insulation under glass fibre mesh under two coat render over torch on felt over cement board over bedding compound finished with Liscanor guillotined stone cladding, roof 200mm fibreglass insulation, windows double glazed low-e argon filled.

[/powerkit_collapsible]

[powerkit_collapsible title=”SUPPLIERS”]

Designer: Mark Salter MIEI, Kinsale, Co Cork, mobile 087 795 1730, [email protected]

Heating system: Alternative Heating & Cooling, Skibbereen, Co Cork, tel. 028 23701, ahac.ie

Ventilation: Aerhaus, aerhaus.ie

Central vacuum: Cyclovac, cyclovac.com

Double sided stove: Boru, borustoves.ie

Windows: Munster Joinery, munsterjoinery.ie

Kitchen: Cullen View Interiors, Riverstick, Co Cork, mobile 086 308 9209, cullenviewinteriors.com

Range cooker: Rose Quartz Lacanche, lacanche.co.uk

Wardrobes: Cork Tile & Wood Flooring, Cork, tel. 021 492 9399

Gas stove: Cork Gas, Cork, tel. 021 496 3749, corkgascentre.ie

Upper level concrete floors: Ducon, duconconcrete.com

[/powerkit_collapsible]

[/powerkit_collapsibles]

So their engineer suggested building new instead. “He told us we had an ideal site to build on, as it was overlooking the farm but far enough to keep the children away. Building new also meant it would be easier to insulate it well.” “We thought it would be difficult to get planning permission but he told us it was worth putting it in to see if we’d get it, so he asked how many bedrooms we’d like and quickly threw together plans. We were stunned when, six months later, our application was approved.”

This was in 2009. “Then the downturn hit and we postponed the build; I was keen to get started but the timing wasn’t right for us. It was only in 2015 that we revived the project,” adds Denise. At this stage they’d sat down to revise the planning drawings. “We kept the shape but reconfigured the inside, we also only kept some of the stone that was originally specified to go all around the house, and we got rid of the cedar cladding due to upkeep.”

‘We had an ideal site to build on, as it was overlooking the farm but far enough to keep the children away.‘

By 2015 Denise and Matt had four children. “We got to really know what we wanted, the older three were past the stage of destroying the place and presented new needs for the family.” They broke ground in August.

Heating courtesy of the milking parlour

Matt and Denise were very hands on from the design stage. “When it came to deciding what heating system to go for we were told oil wasn’t an option – too expensive to run and outdated – so we looked at heat pumps, air source and geothermal,” says Denise.

“In the farmhouse we had an oil boiler, a stove with a back boiler and solar thermal panels. In the new build the most important thing for me was to feel warm in the house.” “We were concerned whether or not a conventional heat pump would actually work and then our heating engineer suggested we look into a system that would use the waste heat from the parlour,” explains Matt.

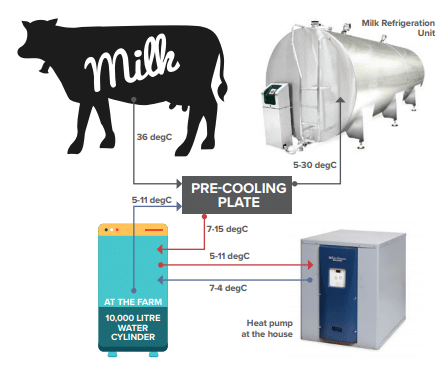

“A dairy farm’s biggest cost is cooling the milk, it needs to be stored at 3.5 degC and comes out at 36 degC.” The premise is simple: the house cools the water that cools the milk, and vice versa, the milk heats the water that heats the house. The set up consists of a heat pump with a 10,000 litre cold water cylinder; the return temperature from the house is 7 degC which helps cool the milk. (See page 35.) There are monitors for the flow and return temperatures, and the tank temperature, all of which are connected to broadband.

“I worked out the heating with the heating engineers, I wanted to use the cooled water back to the parlour which wasn’t originally specified to be used to cool the milk. We looked at our drawings and it seemed like it should work. And it did, we haven’t had any problems,” says Matt.

“At the moment we’re only using half the heat that’s produced, we have too much, in December we only needed about 40 cows to supply the house with heat and hot water, we’re currently milking 150. You need very little energy for the hot water in the summer time.”

In May 2016 they dug the trenches for the innovative system, by August 2016 it was up and running. “We turned on the heating to dry the house out for plastering and painting, it served as a test run too and we were happy to find it worked really well.” Their heating and hot water bill for a full calendar year is €280.

But the system’s reliance on broadband meant it had to be shut down temporarily when work was being done on the phone line over a year and a half ago. “The heating had to be turned off during the maintenance work. What that tested there was the strategy we went for with the walls,” adds Matt.

“We insulated on the outside and the internal walls are concrete to store heat. This was in September and the house kept the heat for a surprising long time.” There’s underfloor heating upstairs and down, with solid concrete floors throughout.

“I thought I’d never be able to live without radiators, I’ve always had them and relied on them to dry laundry,” says Denise. “Matt joked that we’d put the clothes on the floor for drying but actually, if I hang a towel on the back of the chair it dries overnight.” “I’m sure the heat recovery ventilation system we put in helps. Another benefit of underfloor heating is the floor drying 20 seconds after a good mop. I certainly don’t miss the rads.”

‘The finer details take time, get a feel for the place first. Gather as you go along.’

Denise says she finds they are still getting used to the ventilation system as they had some trouble switching from winter to summer mode. “With the warm weather we keep all of the windows open as the ventilation system doesn’t do enough to cool the air coming in, which means it can get very hot at night. We have had the company out a few times and we’re now waiting on a system upgrade.”

The plumbing was done by Denise’s brother and the tiling they arranged on their own, hiring someone that had been recommended.

“All of the rest was done by the builder who came highly recommended, he had built Matt’s parents’ house down the road and pretty much every other house down our laneway so we knew he could deliver,” says Denise. “It was the first time he did an external wall insulation new build, he wasn’t too keen to try something new but eventually came around to it.”

Kitchen at the heart of the home

Their engineer drew up the plans for the kitchen and Denise did the legwork, she went to two different companies to have a look at their showrooms. “Then a friend of mine showed me her kitchen, made by a carpenter, and I loved it,” recounts Denise.

“The island unit is an L shape with a dining area inside; the double sided stove separates the kitchen from the TV room.” “We had to tweak the design, for instance we realised the table would be too close to the fire so we had to move it. The curved views of fields would also have been to people’s backs so we reconfigured around that too.”

“Once the structure was up we used pallets in the empty room to mock up the kitchen and drew on the floor.”

[powerkit_collapsibles]

[powerkit_collapsible title=”Q&A” opened=”true”]

What’s your favourite feature? The farmhouse was at the bottom of the hill and now we’re three quarters of the way up which makes a huge difference. I love sitting at the kitchen, looking out the window and rolling fields – I really didn’t expect such a fantastic view, the factory in the distance, the fields. Funnily enough the garage has even better views of the valley but that’s where we put it in for planning so we couldn’t move it. It’s the plant room for the heating, ventilation and central vacuum. Indoors l love the snug room with TV. The current house has a lot of open space, plenty of light, and it’s very cosy and warm. The patio is also great.

What surprised you? The weight that was lifted off my shoulders moving away from the farm, for the safety of the children. We have the best of both worlds because we can still see what’s going on, we’re near yet there’s none of the stress. We have a sliding gate that means they can’t go out on the road either.

Would you do it again? I would definitely do it again, don’t they say it’s only when you build your third house that you get it right? It was a very exciting experience, and represented a new chapter for us. It gave us more space and more freedom away from the farm.

What piece of advice would you give a budding self-builder? Look for a builder you can relate to and do your research. I spent all my nights researching, went to shows, read magazines, we’d have a completely different house had we built in 2009 and I’m so glad we waited. We definitely wouldn’t have done the heating, so taking the time to evaluate your options is a good thing.

What would you do differently? I would add half a meter to the kitchen dining area – the table is too close to the sliding door, which is behind you when you’re sitting at the table. It’s fine for everyday use but when you have lots of people it can be annoying to have someone pass behind you all the time. I might also move our bedroom to the other side of the house. We currently have the bed in the middle with the wardrobe and ensuite behind but it still feels a bit small to me, even though I don’t need anything more in the room.

[/powerkit_collapsible]

[powerkit_collapsible title=”Top-Tips”]

Check credentials. We didn’t check the references the first painter we hired gave us, and that was the only person we had trouble with. He was very impatient when it came to the second fix because he had to wait for others to finish before he could come in. I contacted him when the house was ready but he failed to show up. We had to get someone else.

Don’t rush. With a young family we had to get all the wardrobes and bathrooms fully kitted out before we moved in, and the kids had a lot of fun choosing colours and decorating their spaces. Despite this aspect, I’d say take your time whereveryou can with the finishes. A lot of things fall into place, I tried to pick out blinds before the build and I was overwhelmed by the variety of colours and styles. I only just got them the other day and I’m really happy I waited. There are things to pick out in advance of course like the kitchen and bathroom but the softer stuff can and should wait. The finer details take time, get a feel for the place first. Gather as you go along.

Have some fun. We thought of the kids a lot during the design stage with the benches, bar stools and the L shape of the kitchen.

Think of where you’ll be charging devices. If I could I would add more sockets in most of the rooms, or change their location. The kitchen is ok but the rest of the house needs more, especially to charge devices. I might also change the placement of some of the light switches so think long and hard about your lighting plan before you sign off on it.

[/powerkit_collapsible]

[/powerkit_collapsibles]

“It’s an in frame kitchen with a granite top – we got samples from the joiner and the fact that he was local meant he came to the house which helped tease out the design. We have a double Belfast sink at the counter and a circular sink in the island.” “I was after ordering a rose quartz cooker so we were limited in the colour scheme we could go for, we chose a light great theme, I definitely took a risk with the pink cooker but we made it work.

The rest of the finishes were also made to match but above all were chosen for dayto-day living. “In the old farmhouse we had laminate in the kitchen which wasn’t easy to clean so we went for tiles this time around. Now the same tiles go to the front door and into the snug.”

“We still designed in a sitting room which doubles up as a study, and there we put in a semi solid engineered wood. Everywhere else we have laminate as wood would be destroyed.” “In the farmhouse we had carpet upstairs, but my boy has asthma so we knew we didn’t want that. Prior to building we’d already chosen to go with mechanical ventilation with heat recovery for the same reason.”

“And even though we didn’t plan for a central vacuum we were asked if we wanted to go with one – I’d heard of problems in relation to storing the hose but this system sucks it back into the cavity and that clinched it for us. There’s an outlet upstairs and one downstairs.” Denise had picked out the tiles in a shop in Cork and put down a deposit but kept going back because she wasn’t really happy with them.

“One day I passed a local tile shop and decided to venture in and they encouraged me to bring samples back to the house, which was really helpful, I was convinced I’d go for a cream, the cream glossy ones were all the rage, but he asked that I take a grey tile back too, I was sure I’d discard it but when I got home I thought wow, that’s the one that feels right.”

“I also got some advice from the tiler, especially for the bathrooms. I once brought back a tile and showed it to him to make sure it was ok, he explained the need to have more of a wow factor in smaller bathrooms and he had a good eye so that also helped us decide.”

Practicalities

Living in a home with young children inevitably requires upkeep. “There is plenty of glass, including on the stairs, so we get a lot of paw prints but that’s the price to pay for openness. A clean now and then does the trick. Most of the build up is at the four year old’s eye level and where the dog jumps up and down to get in.”

“The windows are grey outside and chalk white inside, aluclad because of the style,” she adds. “The house is so well insulated we chose double glazing which already boasts a very good thermal performance. In many new build houses I’ve been in you’re sweating inside and we didn’t want that. We did however go triple glazed at the front door with the double height

windows to make sure the hallway would be well insulated.”

The builder also contributed to the success of this self-build. “He was really helpful, we’d ring him with any question – for the windows we wanted a specific brand and he brought out reps from both companies. We ended up liking his better because the windows looked really good, so he did help guide our decision making.”

“Our builder was a great partner and his experience shone through – he was always one step ahead. At one stage he asked us if we had the internal doors picked out, so we promptly went shopping to choose them (you really need to specify every single detail!) and I decided on the model and he said, great, when we get to that it won’t hold us up. It was so helpful to have him push us in this way.”

As for the design, the configuration works for family life with four bedrooms upstairs. The box room which was originally intended to be the hot press before they decided on their heat pump system, was converted into a spare bedroom. “It doubled up as a room for an au pair when I was working and now we use it for guests, it’s handy to have as a spare. That’s also where

we have the laundry chute.”

Another knock-on effect of their heating system was for the fireplaces and stoves. “We’d originally planned to have a fireplace in the sitting room but we decided to take it out, then when we were building the house we thought something was missing, and that’s when we considered a gas fire.”

“I thought it was too late to add one at that stage but as it turns out we could put in a balanced flue and a false chimney so that’s what we did. We have the gas piped from two bottles, in winter it’s nice to turn on the fire in the sitting room to entertain.”

“The double sided stove that separates the kitchen from the dining area is for effect too, in the farmhouse we used to fill our stove with back boiler all day – with the current set up one and a half fills will do you.” Warm, cosy and tailor made for family life and the farm, this self-build ticks all the boxes for Denise and Matt.

Inside the heatpump

Milking heat from the cows

Mike Cotter of Alternative Heating and Cooling explains the ins and outs of Denise and Matt’s heat pump system.

How was the system designed? It is no different to a regular heat pump installation, the only difference is where the heat is coming from. Instead of extracting heat from the ground or the air we’re getting it from the milk. The controls and the mechanical components are all the same, the heat pump operates as if it was connected to an open loop setup (i.e. a water to water heat pump ).

How was the system designed? It is no different to a regular heat pump installation, the only difference is where the heat is coming from. Instead of extracting heat from the ground or the air we’re getting it from the milk. The controls and the mechanical components are all the same, the heat pump operates as if it was connected to an open loop setup (i.e. a water to water heat pump ).

The pre-cooling plate acts like a switch board; when the house doesn’t need much heat (hot water only) most of the heat from the milk is sent straight to the refrigeration unit for cooling as had always been the case in the parlour. Milk must be stored at 4 degC. When the house does require some warmth, the milk’s heat is extracted into the large water storage tank in the farm yard. This is the heat source for the heat pump and the chilled water source for milk pre-cooling. Any heat recovered from the milk in advance of the bulk milk tank is a reduction in the cooling bill.

In real life the house is benefiting very little in terms of heat pump efficiency, (slight gains over a closed loop collector), the savings are on the farm’s cooling bill.

How much did it cost? A geothermal system for this house, considering it’s 250 metres uphill from the farm and required a large pump to get the water to the house, would cost about €12,000 including VAT. The proprietary components for this cow milking system cost an additional €2,000. Costs are very much site specific. In terms of electricity bills there’s been a huge drop because the milk refrigeration unit, which runs on electricity, has to work a lot less. Year-round the farm’s total electrical bill has reduced since the new house was added to the equation. This is not reflected in the BER rating of the house.

How is it working out? In the summer time, when there’s little demand from the house apart from hot water, the refrigeration unit to cool the milk is used more than it is in winter. Most of the savings come when there’s demand for heat as well as hot water from the house. Most of the winter there’s more heat produced than the house can use but there is a two-week period when a large proportion of the cows aren’t being milked. During that short time frame the heat extracted from the cow’s milk still meets the demand from the house.

Alternative Heating and Cooling Ltd., Unit 3 IDA

Industrial Estate, Baltimore Road, Skibbereen, Co Cork,

tel. 028 237 01 / NI tel. 00353 28 237 01, ahac.ie