An upper floor structure not only allows you to stack an additional living space on top of a lower level, it also provides a conduit for services, i.e. electrics, plumbing and heating pipes, ventilation and where using, central vacuum system pipework.

The cost of an upper floor, be it the first floor or attic floor, will depend on material selection, sound insulation, thermal insulation, fire resistance, structural stability and transfer of services.

Across all floor types, a qualified engineer must review loadings for the specific structure. S/he will design the size, depth and makeup of the supports to meet with the requirements of that material when compared to the layout of rooms, the span of floors, etc., all in accordance with the Building Regulations.

What follows is a general description and comparison of various floor types, but excludes any additional structural steel, upgrade in load bearing wall makeups, etc.

Traditional Cut Timber Floor Cost

The main factor that impacts on the cost of a floor in a domestic property is the choice of material used in the structure. Historically, and back in our grandparents’ days, timber enjoyed a virtual monopoly in terms of floor structure makeup. Kiln-dried softwood joists spanning between structural walls were the product of choice. Once the blockwork lift from ground to first floor was completed, a carpenter arrived on site and installed timber joists across the floor.

Internal load bearing walls were used as resting points for the timber on mid spans (timber joists typically span up to 4.5m in length) with additional joists installed between the main runs as supports (known as struts or bridging). The joist ends are built into the blockwork of the external

walls or they are installed into joist hangers.

The void in the floors can then be used to run services around the building, the underside can be clad with plasterboard to form the ceiling of the room below and the top side can have a floor board (plywood, OSB board, or a traditional tongue and groove floorboard) installed

to form the floor of the room above onto which a selected finish can be installed.

To provide sound insulation and fire resistance, the voids tend to be filled with mineral wool. The downside to this type of floor, as anyone who has lived in a property with this makeup can attest to, is that timber has a tendency to suffer from shrinkage which results in many of these

floors becoming squeaky over time.

One of the biggest issues with timber floors is the difficulty of sound transfer from the impact of walking. To mitigate this, products can be installed, e.g. a rubber membrane produced from recycled tyres or a thick underlay between the timber floor and any finish such as carpet which also muffles noise.

Other products are available that can be installed along the top of the joist, to prevent impact noise, between the joist and the timber plywood or other boarding installed to achieve a reduction in this transfer but overall it can be difficult to limit the impact.

Timber I-Joists

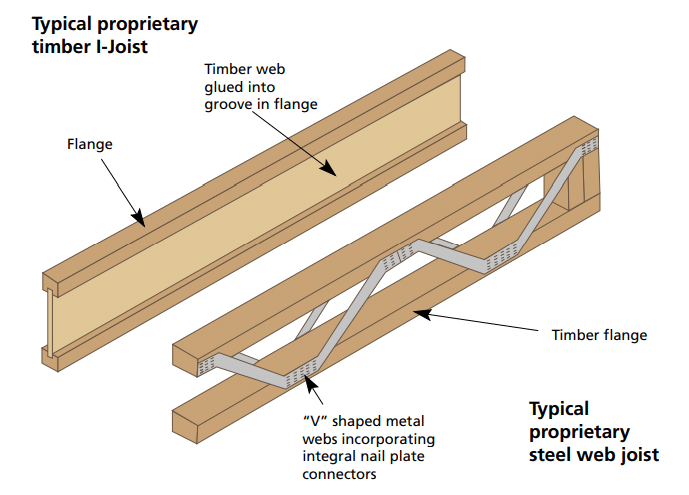

Now a more common approach to timber joists are the installation of factory-made timber I-joists, or I-beam as they are commonly referred to. These joists are manufactured using an I shaped cross section made up of softwood or laminated veneered timber bonded to a centre web of OSB or another engineered board.

They are strong, lightweight and can span over 6m without the need of internal wall or beam support. They are also not prone to shrinkage and therefore avoid the squeaking issues of traditional timber joisting. However the issue of the sound impact of walking across the floor will be similar to that of traditional joists.

The webs can be drilled for services which can be carried in the void of the floor. As with traditional joisting, plasterboard can be fixed to the underside and floor boarding to the top to provide for room finishes. Insulation can also be placed between the joists as necessary.

Open metal web joists

Similar in look to the I-Joists, metal web joists have a wavy metal web centre that facilitates the running of services without any need for drilling. They are extremely strong and yet easy to carry and install, and not prone to shrinkage.

They can achieve unsupported spans of 7.5m across a range of depths from 195mm to over 300mm. Similar to traditional joisting, plasterboard can be fixed to the underside and floor boarding to the top to provide for room finishes. Insulation can also be placed between the joists as necessary. Again, the issue of the sound impact of walking across the floor will be

similar to that of traditional joists.

Timber frame construction

Timber frame companies will cost their proprietary systems as a whole but in the main many will use one of the systems above. It will be necessary to check the specification of each to confirm exactly what system you are receiving a quotation for.

Hollowcore precast concrete

The installation of precast concrete floors to first and subsequent floors has increased in popularity over the recent past. Manufactured in a factory, transported to site and lifted into position by crane, they are quickly installed and provide a robust structure.

By far the most common type of concrete floor, precast hollow core flooring is comprised of precast concrete with voids running along the length of each slab, thereby reducing the weight.

The slabs come in various thicknesses and spans from 100mm to 300mm. They provide a high level of sound insulation and fire resistance but present difficulties in terms of routing services and in most cases additional timber battens will be required on the underside of the floors to form a services void between the underside of the slab and the plasterboard of the ceiling below.

The cost of coring the hollow core floor for service voids is far greater than any of the timber systems outlined and care is required in respect to planning well ahead for where all of the services will go. Whether drilling through timber or concrete, structural considerations are also at play and an engineer should be consulted before doing so.

In addition, and depending on the system used, it is common for there to be a structural screed and reinforcement mesh installed to the top of the slabs to tie the floor together. In most instances this screed will also incorporate the underfloor heating pipework for the floor.

Whereas underfloor heating is possible with timber floors, with the help of thin quick drying screeds, it is more commonly used where precast concrete floors have been installed. Any selected floor finish can then be installed on the concrete floor as directed by the manufacturer of the finished product.

One of the biggest benefits of a precast concrete floor is the elimination of the issue of sound from the impact of walking being transferred to rooms below. Care is still required in respect to the need for sound absorbing products between the concrete floor and any selected finish, but

overall the floor works well in removing sound transfer issues.

Cost comparison

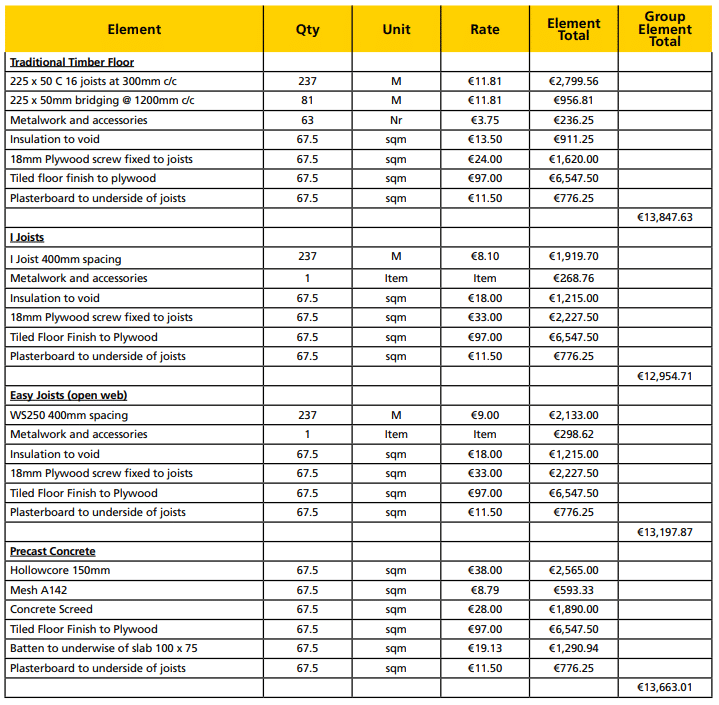

The table below shows the notional costs of a property with a 67.5sqm first floor area; the analysis excludes openings and accessories. For comparative purposes all costs include standard 12.5mm plasterboard to finish the ceiling below and a tiled floor finish on the floor above, with an allowance of €50/sqm for the purchase of the floor tiles (excludes installation cost).

When we revert back to the example of our two 139sqm properties that we have been comparing in our articles to date, the bungalow and the two storey property, as the bungalow does not have any intermediate floor the cost of the two storey property would be double as it would have to factor in an attic floor.

Try our new ‘Selfbuild Cost Calculator’. Fill in details and instantly get a rough estimate for your project